Rus Emerick, Global Process Owner for 3D Imaging at Schneider Electric, spends a lot of time thinking about tolerances. Starting with tolerances of individual parts, his brain moves swiftly on to the effect of chains of tolerances that, once you get to 4, 5 or more parts in an assembly, could cumulatively affect the reliability of the products being made at any of their manufacturing and design sites in 22 countries around the world. But how can the consistency of assemblies be verified before and during production? Using traditional destructive testing was proving inefficient, slow and often did not help the team verify consistency in the parts and assemblies. Dynamic tolerance analysis of these assembled parts was even more of a challenge. Money was being wasted. There had to be a better solution and Emerick knew that 3D data would continue to provide the answers he needed.

Rus Emerick, Global Process Owner for 3D Imaging at Schneider Electric, spends a lot of time thinking about tolerances. Starting with tolerances of individual parts, his brain moves swiftly on to the effect of chains of tolerances that, once you get to 4, 5 or more parts in an assembly, could cumulatively affect the reliability of the products being made at any of their manufacturing and design sites in 22 countries around the world. But how can the consistency of assemblies be verified before and during production? Using traditional destructive testing was proving inefficient, slow and often did not help the team verify consistency in the parts and assemblies. Dynamic tolerance analysis of these assembled parts was even more of a challenge. Money was being wasted. There had to be a better solution and Emerick knew that 3D data would continue to provide the answers he needed.

Schneider Electric has been in operation for more than 170 years, evolving through iron and steel, heavy equipment and into electrical and automation management products. Products and services cover electrical distribution, industrial automation, critical power & cooling, building management and security, with manufacturing plants at key manufacturing centers across the world.

In the space of an hour I solved a problem that would normally have cost 21 days of production in downtime. That’s an easy $480,000 saved in a single hour of 3D scanning and verifying the problem inside of Geomagic Qualify,”

Emerick, a specialist in Process Improvement, is something of a trail-blazer in the organization, finding and implementing solutions that are designed to improve 6 Sigma practices, working with production teams on supporting lean manufacturing techniques in an effort to reduce costs and waste in the engineering-to-production workflow. His work is to design processes that can be methodically implemented across each of the manufacturing plants, allowing best practices to become standard at each site. His focus is on verification of products using 3D data. For 10 years, he has worked very successfully with automated inspection in the production lines, using Laser Designs’ Surveyor 3D scanners and Geomagic Qualify to measure, inspect and report on products. Since the demand for better, more efficient manufacturing never lets up, so Emerick keeps the pressure on his team, some 125 strong, to find new, faster and better ways for 3D data to improve product quality.

“It is a requirement of our products that they have to work unattended for a period of years. That means we have to guarantee quality,” he says. “How can we assure that the circuit breakers in that server farm will be perfect when that power surge hits? What about a transformer, out in the middle of nowhere in hostile weather conditions, that has to work up to and beyond its guaranteed life? The products have little room for failure, peoples lives can depend on them, and it’s up to us to ensure something close to perfection before the products are released.”

In pursuit of this mission, Emerick started experimenting with CT scan data about 3 years ago.

“Laser scanners see what’s on the outside –a single part or a housing. In those terms we had the process perfected,” he says. “The interaction of parts in an assembly, however, could only be verified through destructive testing – you know, the old way: take the first 100 products, open them, look at them, test them, destroy them.”

The team tried to add analysis software into the process but it didn’t help much with dynamic forces when applied to the assembly.

“When force is applied it may bend or warp the parts,” says Emerick. “Under dynamic force in the real world something can happen to a key part, but you can spend all day in analysis software and you can’t predict the reason. You have to be testing on the real assembly to verify how they will work.”

“When force is applied it may bend or warp the parts,” says Emerick. “Under dynamic force in the real world something can happen to a key part, but you can spend all day in analysis software and you can’t predict the reason. You have to be testing on the real assembly to verify how they will work.”

Emerick knew that he had to analyze the root cause of any problems as a product came off the production line.

“We can’t sell a product if it has a flaw. So every day saved is an extra day’s profit. If we reduce time-to-market by 50% then we reach our customers in half the time, which means the company realizes earlier profitability.”

But the tradition of destructive testing remained: “The problem is that with this process you just destroyed your sample, and during that time you proved that 65 out of 100 were perfect. But you just don’t know that you will get the same result with the next 100… it is a total leap of statistics and faith.”

CT scanning became de rigueur in medical procedures many years ago, but in recent years has become of interest in industrial processes. Emerick was also interested. He checked out and tested multiple systems, eliminating the older-style fan beam system that delivered a horizontal beam through an assembly with minute increases in height, which delivered thousands of stacks and took forever to scan and process. He found some systems that were faster but used magnification in the scan which made the results subject to error and thereby suspect.

After 3 years of testing and learning, Emerick finally found the state-of-the-art version he was looking for: a Zeiss METROTOM 1500 CT scanner provided through Laser Design Inc. “Schneider Electric understands the importance of analysis in their fabrication and qualification processes,” explained C. Martin Schuster, President and CEO of Laser Design. “Our ultra-precise CT scanning system from Zeiss provides the Schneider plant with assurance of their parts’ and assemblies’ geometry, including internal features. All dimensions of parts are accessible and measurement accuracies are unparalleled.”

Laser Design provides ultra-precise 3D scanning systems and 3D measurement services, helping customers successfully complete complex inspection, analysis, and reverse engineering projects for more than 30 years. The company has various 3D systems installed worldwide in demanding applications throughout many different industries, government agencies, universities and museums.

Laser Design provides ultra-precise 3D scanning systems and 3D measurement services, helping customers successfully complete complex inspection, analysis, and reverse engineering projects for more than 30 years. The company has various 3D systems installed worldwide in demanding applications throughout many different industries, government agencies, universities and museums.

The Zeiss Metrotom 1500 CT scanner captures all surfaces, both external and internal, of complex free-form parts and assemblies without harming the object. Parts made of plastic, ceramics or composite materials, as well as magnesium, aluminum and steel, can be measured and efficiently evaluated. A very long service life is enabled by the open X-ray tube technology and it has a measurement range of 11.8″ x 13.8″ (300 mm x 350 mm). The CT system can also be equipped with a higher resolution detector to make very fine part structures visible, and the enlarged detailed view can be measured with extremely high accuracy.

But, could it achieve what Emerick required?

“Using the CT scan, no surface does not turn up,” he says. “With an accuracy of 11 microns, with a scan completed in about an hour, we suddenly found that we could see, measure, compare and report on a product very quickly – without having to destroy it in the process.”

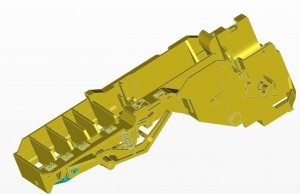

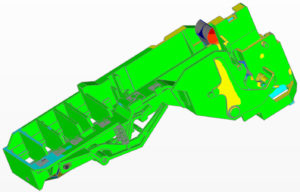

Processing the CT scan data through Volume Graphics, the 3D model is then loaded into Geomagic Qualify where the assembly is compared to either original CAD design data or to scan data of another known working product. Geomagic Qualify quickly and automatically measures and assesses deviations between the new scan data and the comparison assembly model, making measurement on known tolerances, identifying deviations in the assembly based on unanticipated forces between parts. Geomagic Qualify then automatically produces a custom report for the production engineers in PDF, so it can be viewed by all concerned parties.

Each scan of an assembly takes less than an hour, and the images from the CT scan are already compressing and processing even while the scan continues.

“Because of the speed of processing and the rapid output of Geomagic Qualify, we can verify if an assembly is hitting the right tolerances within an hour. This is breathtakingly fast for a process that would have taken days using destructive practices” says Emerick.

“Because of the speed of processing and the rapid output of Geomagic Qualify, we can verify if an assembly is hitting the right tolerances within an hour. This is breathtakingly fast for a process that would have taken days using destructive practices” says Emerick.

This kind of rapid turnaround is key to the entire organization: if there is a problem on the production line, production has to stop until it is resolved. A typical circuit breaker line will produce 80,000 circuit breakers per day in optimal conditions. Every hour, indeed every minute spent resolving a problem costs the company money.

“In the space of an hour I solved a problem that would normally have cost 21 days of production in downtime. That’s an easy $480,000 saved in a single hour of 3D scanning and verifying the problem inside of Geomagic Qualify,” he says.

Beyond the basic CT scan

According to Emerick, CT scanning is able to take their processes way beyond the simple need to measure and verify: It is helping them reduce scrap, errors, verify assemblies and even has the level of detail to allow them to see and identify cracks and bubbles inside materials that could reduce the life span of the products.

“This is a key part of significantly improving our testing,” says Emerick. “Traditional verification usually involves dimensions. With certain materials manufacturing, measurement cannot tell you if the production is running too hot, or with enough glass – variables that destructive testing might be able to verify but then we are back to square one in terms of ongoing, consistent verification of parts.”

Rus Emerick is excited about the success with the industrial CT scanning, enough so that he hopes one day to introduce this across the company’s worldwide operations. But in between production line verification, he is also using the device to create a virtual 3D warehouse of data – a store in the company’s MRP system that archives known working assemblies for later use as a reference for ongoing production challenges. And in the meantime, he will continue to think about tolerances. Just like he always has.