Nondestructive, 3D Scanning of Internal and External Geometries

Give our 3D Scan team a call! 952-252-3479

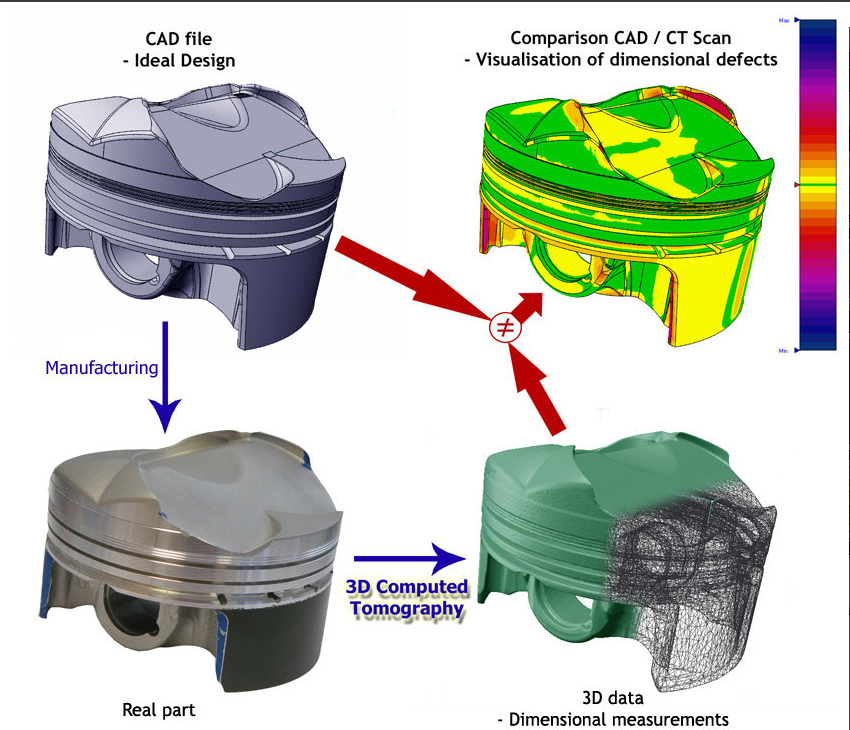

Metrology grade Computed Tomography (CT) inspection allows a complete 3D capture of complex internal geometry of parts without needing visual access – the process is nondestructive. Have your complex parts 3D scanned and inspected for complex internal and external geometry with Industrial X-ray 3D scanning.

Metrology grade Computed Tomography (CT) inspection allows a complete 3D capture of complex internal geometry of parts without needing visual access – the process is nondestructive. Have your complex parts 3D scanned and inspected for complex internal and external geometry with Industrial X-ray 3D scanning.

Benefits of CT Scanning for Your Parts:

-

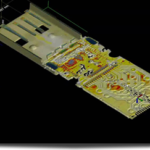

- Non-destructive inspection of your parts; line of sight or visual access to any surface is not required for CT scanning, yet 100% of the surface data is captured Your object, material or system will not be compromised or impaired, so its future usefulness is kept intact

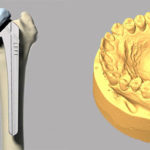

- CT Scanning can provide accuracy on small parts of +/-0.010mm and on larger parts of +/-0.025mm (depending on size of part)

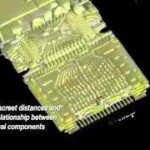

- Parts with small, complex, and fine geometry from the medical and electronics industries benefit especially from this technology, since they are very difficult to measure using even the most advanced, laser-based scanning or CMM technologies

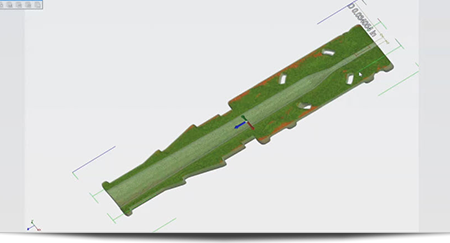

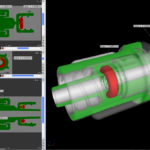

- Customizable two- and three-dimensional inspections of small- to medium-sized objects generate 3D XYZ scan data in standard file format outputs for inspection and reverse engineering applications.

- CT scanning helps you capture all surfaces, both external and internal, of complex and free-form parts without damage to the object.

Our engineers utilize Volume Graphics and other software programs for your CT inspection needs. Volume Graphics provides analysis and visualization software for industrial CT scan data and is the premier digital workflow management software for CT analysis.

Our expert metrologists will provide you with excellent quality data processing, modeling work, speed and accuracy.