Situation

Situation

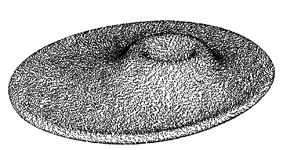

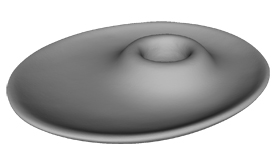

Scaling hand made sculptures is extremely difficult, time consuming, and sometimes impossible. Urbana needed to create a master pattern of their hand made sculpture for plaster casting.

Since the plaster would shrink after production a scale factor up from the originally had to be used, but to do this without scanning would mean creating several very similar parts for the various production methods.

3DScanCo has remained in contact with ARINC and worked hard to give us a deliverable in the desired format and having the characteristics that our project requires.”

Solution

Solution

Urbana contracted 3DScanCo – a division of Laser Design Inc. – to three scale models of this hand made designer pot. The three scale models were necessary to compensate for part shrinkage after casting. By using 3D scan data Urbana was able to create a single hand made sculpture and scale it to the various necessary sizes.

Results

Results

3DScanCo’s scanning services provided Urbana with precisely what they needed – Three scaled models of their hand made designer pot. Urbana was was able to save a tremendous amount of effort in the design process by using 3D Scan Data.

Without using 3D scanning it would have been necessary to tediously match the three hand made parts to ensure they final products all looked the same. 3DScanCo allowed Urbana to achieve a design consistency never before matched.