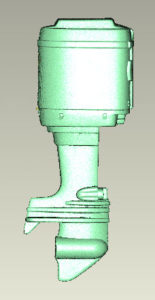

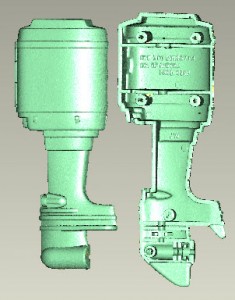

John purchased a miniature motorized “toy” outboard motor from Ebay and wanted to reproduce using a more substantial motor/gearing set up for R/C use. The outboard is 6 inches tall and the two halves can separate to easily remove the internal components.

John purchased a miniature motorized “toy” outboard motor from Ebay and wanted to reproduce using a more substantial motor/gearing set up for R/C use. The outboard is 6 inches tall and the two halves can separate to easily remove the internal components.

He contacted an RP company but quickly realized he would need a 3D Solidworks model first. Laser Design Services scanned the outboard motor for a RC device and gave him CAD models and ABS prototype part in about 8 days.

Since then John has installed a higher horsepower motor and it is operational. He’s thrilled with the results wanted to share the images with our 3D scanning community!

Laser Design Steps in this project were:

1. Receive and scan the parts with our high-accuracy 3D scanning system

2. Process the files into Solidworks models with a STL polygon export of each part for ABS printing.

3. Print the parts in black ABS resin using FDM technology for strong functional parts.

4. Ship the parts and originals back to customer.