Situation

Situation

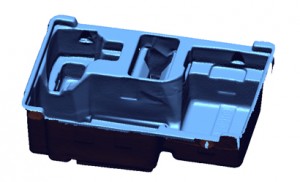

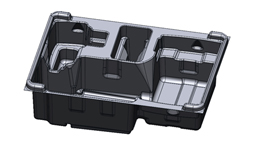

Panoramic Inc., a designer and manufacturer of custom thermoformed plastic packaging products, needed to reverse engineer existing paper packaging to create new plastic packaging.

The existing paper packaging held consumer products, no CAD of the consumer products or the existing packaging was available for Panoramic to design new plastic packaging from. Panaromic needed to quickly create a CAD model so they could cut new thermoform tooling.

We look forward to working with 3DScanCo for any type of 3D scanning work. They have earned our trust, the highest praise.”

Solution

Solution

Panoramic contracted 3DScanCo -a division of Laser Design Inc – to create new CAD models of the existing packaging. 3DScanCo used high resolution 3D laser scans from the Konica-Minolta Vivid 9i to create a point cloud of the existing packaging.

The point cloud was then used in Rapidform XOR to create Solidworks models of the existing packaging. 3DScanCo was able to hold a very high tolerance to the original packaging and was able to continuously monitor the accuracy of the model using the Accuracy Analyzer.

Results

Results

This project resulted in Solidworks model that Panoramic was able to use to create new thermoformed plastic packaging from. Using 3D Scan data, Panoramic was able to drastically reduce the amount of time in reverse engineering the existing packaging resulting in a faster time to market with their final product.