Situation Engineers often need to design parts that fit inside objects that lack CAD data. The measurements of these legacy parts are typically obtained via calipers or a Coordinate Measuring Machine (CMM). However, these methods often suffer from human error or cannot sufficiently measure the complex surfaces. Engineered Plastic Products, Inc. needed accurate models of a pair of OEM motorcycle chain covers in order to design new pieces to fit within the physical part. For EPP to ensure that the

Elan Motorsports Discovers Solution to DP02 Racer Dilemma

Situation Elan Motorsports uses a standard fiberglass lay-up process to create the shell (outer body mold) of their VanDiemen DP02 Sports Racer. Based off the model design of an existing racer body, Elan needed to know the shell’s dimensions in order to correctly place the engine and chassis. The DP02 also required optimization of packing density and weight ratios in order to maximize the performance of the car. Due to the complex and free form surfaces of the shell, as

Computational Methods

Situation Only recently has modern 3D scanning technologies been able to catch up with the demand for accurate scanning of large physical objects. Digital models of massive aircraft such as the Airbus A319 can be tested via computational fluid dynamics (CFD) if the model is accurate enough to the actual physical shape. 3D scanning technology is the most effective way to ensure this accuracy. Computational Methods, an aerodynamic analysis company, needed surface data of the Airbus A319 to model and

3D Scan of Three million-year-old Horse Skull

The National Park Service’s Hagerman Fossil Beds National Monument in Idaho contains the largest concentration of Hagerman Horse (Equus simplicidens) fossils in North America. It is nationally and internationally significant for its world-class paleontological resources including the world’s richest fossil deposits, in quality, quantity, and diversity, from the late Pliocene epoch. Many of its fossils represent the last vestiges of species that existed before the last Ice Age, the Pleistocene, and the earliest modern flora and fauna. The NPS paleontologists

Improving Comfort and Safety for Elite Racecar Drivers through Custom Seats and Headrests

Situation BSCI Energy Impact Systems is a leader in the development and research of foam safety components and has pioneered innovations that have set the industry standard in professional racing. BSCI’s successes are driven by their understanding of the importance of properly designed and functioning padding inside the car – padding that helps protect drivers from the tremendous forces applied during a crash. Top drivers from around the world come to BSCI for custom-fit seats that perfectly match the shape

NASA’s Aeronautical Research Lab Flying High With Critically Modified Fairings

Situation In 1994, NASA obtained a specially modified Boeing 757-200 to be used for aeronautical research. Named the ARIES, or Airborne Research Integrated Experiments System, the aircraft has gone through numerous customizations and modifications to earn its “flying laboratory” nickname. Over time, NASA realized that in order to maintain the ARIES as its premier research aircraft, they would need to modify the fairings. In order to do this, NASA would need much higher quality CAD data of the jet in

High-Quality Medical Training on Airway Replica Maintained Using Breakthrough Internal 3D Scanning Process

Situation Medical training programs are the cornerstone of successful medical practice. Medical Education Technologies Inc. (METI), a developer of medical training products, lost its only supplier of the PediaSIM® airway, leaving them with physical models, but no CAD data and no way to manufacture them. Not wanting to completely redevelop the product, METI sought to reverse engineer CAD data from the limited number of physical parts they had left. METI made several attempts to reverse engineer the design. However, the

Labor-Intensive Prototyping Cycle for Marine OEM Products Streamlined with 3D Laser Scanning

Situation Engineered Metals and Composites, Inc. (EM&C) is the premier OEM manufacturer of aluminum towers and small products for the marine industry. From T-tops, hard tops and towers, to rod holders, leaning posts, rails and poling platforms, they provide the highest quality enhancements and accessories for fishing and pleasure boats. In order to create these products, EM&C’s craftsmen design and manually shape the towers to fit the boats, which can be a laborious and time-intensive process. For EM&C to maintain

Troops Protected through Precise Life-Saving Up-Armoring of Trucks

Situation The vast amount of supplies being sent into Iraq has been key to the U.S. Military’s efforts in the region. Convoys of trucks loaded with supplies have been entering Iraq from Kuwait for the past several years; however, the lightly armored trucks offer very little protection for the drivers against projectiles and explosives. DRS Radian was contracted to develop armor kits for several models of trucks in order to ensure the safety of the drivers. However, CAD data was

Perfect CAD Data Enabled CAE Precision Testing on MC-130E Radar System

Situation Since its introduction in the 1960s, the MC-130E Talon I has been modified on a nearly continuous basis to incorporate more and more modern technology into its legacy design. One such addition is of a state-of-the-art radar system which would be housed inside a radome that was hand-crafted from fiberglass in the 1950s. Computer Aided Engineering (CAE) would have to be performed by MI Technologies to test a variety of functions of the radar system inside the radome. In

SEMA’s Best New Interior Product: Deep and Precisely Fitted Jeep Floormats

Situation Omix-Ada is the premier manufacturer of Jeep replacement, restoration and accessory products, including the Rugged Ridge accessory line of floormats. Currently, Jeep floormats are either “carpet,” thermoformed rubber that fits the car, or “deep” all-weather flat floormats that are not formed to fit. Omix-Ada wanted to combine the advantages of both types of mats to create OEM-quality mats that are both formed to the vehicle and deep. However, they needed help in both capturing the exact cab floor geometry

3D Laser Scanning Assures Fit, Lowers Cost, Speeds Production for Automotive Aftermarket Manufacturer

Situation Aftermarket manufacturers are unable to fully take advantage of OEM CAD data because of the slight variations between the CAD data and the as-built part, especially for body panels. Furthermore, automakers offer their own competitive in-house brands as an alternative to third-party companies. United Covers, Inc., an aftermarket parts manufacturer, had invested in a touch probe system in order to obtain the surface data necessary for their line of custom fender trims. However, the amount of data the touch

National Treasure Restored to Former Glory through 3D Laser Scanning

Situation The Rotunda of the National Archives Museum is the final resting place of the Declaration of Independence, one of our nation’s most treasured documents. Over time, the unique hand-crafted frame has become worn down, leaving its intricacies muted and details eroded. Manufacturing at the turn of the century was mostly done by hand, therefore there is no record of the original design from 1924. Several attempts were made to recreate the frame using conventional bronze sculpting techniques. The results

Turbine Blades Reverse Engineered to Strict FAA Standards with 3D Laser Scanning

Situation The affordability, efficiency and quality of the turboprop engine has spurred its widespread use in various industries since its entry into the market. Acme Turbine Company*, a turbine blade manufacturing company, wanted to gain a competitive advantage by producing superior blades at a lower cost. However, they lacked CAD data for their blades, prompting their need for a reverse engineering solution. The FAA imposes strict standards on the certification of airplane parts due to the inherent safety risks associated

Laser Design Assures Accessory Fit on Tricked-out ATV

The Company: The Minnesota company is a leading manufacturer of high quality ATV, snowmobile and motorcycle parts and accessories. Serving both OEMs and the aftermarket, the full-line manufacturer offers everything from product development and design engineering to complete steel fabrication, including stamping, tube bending, robotic welding and assembly. The Challenge: The company designed and manufactured a prototype snow blade for the Yamaha Grizzly ATV. Previously, to mount it they had measured the mounting locations by hand. However, they oftentimes found

United States Department of Energy

Situation The US Department of Energy has funded the Princeton Plasma Physics Laboratory for advanced research in fusion power. Using a device called a stellarator, the PPPL has been able to generate a million-degree fusion reaction that is magnetically suspended inside the stellarator’s experimental and unique shape. The shape of the casting is critical to the suspension of the hot plasma, preventing a meltdown of the entire reactor. The industry’s conventional inspection techniques were insufficient at detecting defects in the

NASA

Situation NASA routinely performs maintenance and repair on the 40,000+ unique heat resistant tiles covering the space shuttle. Tiles are usually repaired by removing them, filling the space with plaster, and then machining a new one based on the shape of the plaster. The new tiles must be made accurately to keep an airtight seal between them – any hot gasses trapped behind tiles during reentry could cause them to fail. NASA needed to upgrade their tile-repair system to an

UH-1Y “Huey”

Situation Bell Helicopter’s “Huey” is one of the world’s most recognizable helicopters. Primarily used by the US Marine Corps, the current model UH-1Y’s design stems from the original UH-1 developed in 1955. Manufactured in Amarillo, Texas, Bell uses a system of templates to assemble the helicopters. These templates are physical masters, and most have no known documentation. Bell Helicopter sought to transfer the production site of the cabin from their plant to one operated by Crestview Aerospace without stopping production.

Acme Molding Company: Soap Bottle Mold

Situation Companies working with molds must often make changes to the shape of tooling right on the shop-floor. These continuous improvements are necessary to avoid delays in production due to imperfect manufacturing results. However, these hand-finished changes result in a mismatch between the tooling’s original CAD model and the actual physical mold. One of the world’s leading liquid packaging firms made shop-floor changes to the tooling of a soap bottle in order to adjust the volume of liquid the bottle

1st Virtual: 1:500 Scale Napoleonic Figurines

Situation Miniature figurines have long been a source of interest for collectors and military enthusiasts. Historical battles can be completely recreated on a small scale with hundreds of figurines, each one representing a regiment or battle group. 1st Virtual Productions sought to recreate the entire Battle of Waterloo, this time with a 1:1 ratio of figurines to actual soldiers. In order to fit the thousands of soldiers in a reasonable area, 1st Virtual would have to scale them down to

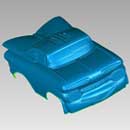

Toy Car to Life Size: Fast, Accurate Scaling for Fun Commercial Application

This type of commercial application showcases the remarkable capabilities of 3D laser scanning to accurately, completely, and quickly facilitate changes in scale; small items can be made larger to scale or larger items can be scaled down. The Challenge: To scan a small complex object and create cross sections to represent the internal structure used to build the objects on a larger, life-size scale and to generate DXF curves needed for the CNC wire bending operations involved. An STL file

As Featured in Medical Design Technology: Applying Tech Orthopedics

How are you influencing Orthopedic Devices? By Larry Carlberg, Laser Design Service Bureau Manager, Laser Design Services Orthopedic devices, with their focus on fit and support for the human form, are advancing rapidly as we learn more about how to optimally heal and rehab injuries. Laser Design Services specializes in 3D laser scanning, which can produce a fast, precise CAD model of whatever body part is affected, thus ensuring that the orthopedic devices professionals use with their patients are customized to prevent

30 Years of Scanning Excellence with GKS Services Corp.

GKS Services Corp., a subsidiary of Laser Design Inc. and international leader in providing 3D scanning services, was founded in 1981 as a scanning services bureau. The company has grown in its 30-year history to become a sought-after expert in dimensional inspection, 3D laser scanning, computed tomography (CT) scanning, long-range scanning, laser tracking, and engineering services such as product development and design, rapid prototyping, and manufacturing services, completing well over 20,000 projects. We are expanding the GKS division worldwide, and

Laser Design Inc: Innovator in 3D Laser Scanning Industry

Back in the mid-1980s entrepreneur C. Martin Schuster had a novel idea: Use line-laser scanning to accurately digitize and model complex 3D shapes so they can be used in CAD/CAM systems for industrial manufacturing. Laser scanning technology was in its infancy and using it to capture three-dimensional whole-part geometry was revolutionary for the time. After a few years of percolating his idea, Schuster incorporated as Laser Design Inc. in 1987 with an innovative, talented group of engineers and software developers.

Whatever Floats Your Boat: Hand-Made Prototype to Advanced Manufacturing Process

Company: The Minnesota company designs and manufactures a unique line of small electrically powered watercraft inspired by the enjoyment of personal recreational experiences up-close in the land of 10,000 lakes. Challenge: The small fiberglass boat was designed and prototyped by hand, which meant that it was not totally uniform and symmetrical. As the company was preparing to scale up production volume, their suppliers began requesting CAD data of the deck and hull so they could precisely make and fit ancillary

- « Previous Page

- 1

- …

- 7

- 8

- 9

- 10

- Next Page »