3D Scanning for Architecture, Engineering & Construction

From the design stage to the inspection stage, 3D scanning and measurement is an integral element of architecture, engineering, and construction. Our terrestrial scanning services can save you hundreds of hours on planning time and misspent labor.

Laser Design’s 3D terrestrial & LiDAR specialists have experience with new construction, renovation, historic preservation, and building inspection projects around the world. From historic homes to international airports, terrestrial scanning services is an ideal 3D as-built documentation solution for any building project’s needs.

Benefits of 3D Scanning Services:

- On-site 3D scanning of your site that is virtually unlimited in size and environment including broad daylight, the dark of night, indoors, and outdoors

- Receive complete documentation of existing as-built conditions

- Obtain permanent records for immediate or future uses

- Save time and cost by reducing your time with cameras and measurement devices

- Increase safety in unsafe locations

- 3D Scan and replicate sites and ornate details

- Verify architecture of floors, walls, buildings & more – this terrestrial (or static LiDAR) technology is great for the AEC/AEP world!

- and many specific benefits based on your industry and application!

3D Scanning Deliverables:

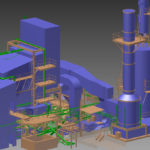

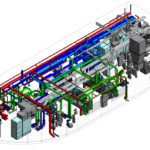

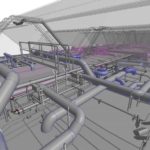

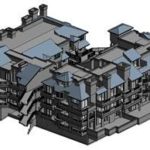

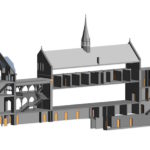

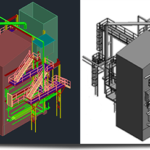

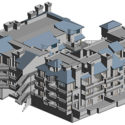

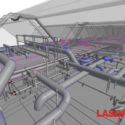

- 3D CAD Models

- BIM Integration

- As-built Documentation

- Fly-through and presentation capabilities with more accuracy than photos or video alone

- Point Cloud Data

- Elevation Drawings

- Plan View Drawings

We also sell long-range Artec Ray for your long-ranging scanner needs!

Ask a 3D Expert - Microsite

What is 3D Terrestrial Scanning?

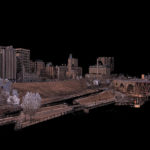

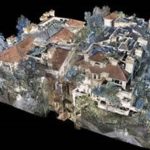

Terrestrial & Mobile 3D scanning are techniques for collecting high-density spatial imaging with millions of coordinates quickly and accurately.

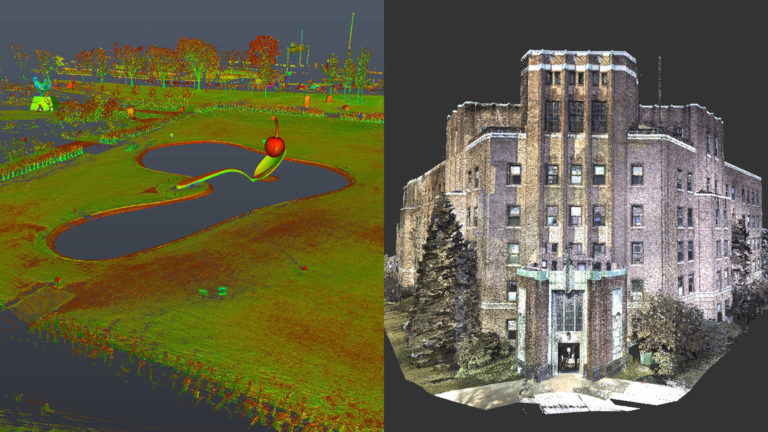

Using highly accurate 3D scan data generated with 3D scanning you are able to view as-built documentation in a virtual world. The point cloud data can also be surfaced to generate a CAD model which can be used for comparison or reconstruction.

The size of the specimen being scanned is no longer limited to the directional travel of a machine, or the reach of an arm. Scans can be taken anywhere, at virtually any time. The raw output of terrestrial scanning is “point-cloud” data, which we can use as reference to create a fully parametric file in your design software.

Laser Design uses top of the line 3D software systems and software for your project! We have experience with the latest technology and always pick the right software and 3D system for your job to ensure the best results.

3D Terrestrial Scanning Photo Gallery

The Laser Design Terrestrial 3D Team has been busy! We’ve been to the World Trade Center, the new U.S. Bank Stadium, Space Needle, Miami Airport, ships in Korea, the Mirage volcano and more! We have the experience and know-how to tackle your next project! Check out our gallery of photos.

3D Scanning Videos: AEC

3D Terrestrial Scanning Case Studies and News

-

AEC 3D Scanning for Metal Panel Design

AEC 3D Scanning for Metal Panel Design

-

As-Built Documentation Using 3D Scanning: 5 Benefits of 3D Scanning for Design, Engineering and New Equipment Installation in Commercial Buildings

As-Built Documentation Using 3D Scanning: 5 Benefits of 3D Scanning for Design, Engineering and New Equipment Installation in Commercial Buildings

-

5 Advantages 3D Scanning Provides for Building Information Modeling

5 Advantages 3D Scanning Provides for Building Information Modeling

-

Application Story – 3D Scanning and Projection Mapping

Application Story – 3D Scanning and Projection Mapping

-

3D Scanning of Basilica – Norfolk

3D Scanning of Basilica – Norfolk

-

3D Scanning of Mechanical Rooms

3D Scanning of Mechanical Rooms

-

Pacific Eagle Uses 3D Scanning to Rental Units into Condos

Pacific Eagle Uses 3D Scanning to Rental Units into Condos

-

3D Scanning of a Hospital Boiler Room

3D Scanning of a Hospital Boiler Room

-

3D Terrestrial Scan of Shattuck St. Mary’s

3D Terrestrial Scan of Shattuck St. Mary’s

-

Municipal Cooling System Replaced with Minimal Downtime through 3D Scanning Services

Municipal Cooling System Replaced with Minimal Downtime through 3D Scanning Services

-

Long-Range Scanning Busts Crunch-Time Large-Scale Project Deadline

Long-Range Scanning Busts Crunch-Time Large-Scale Project Deadline

-

Digital Recreation from the Scene of the Accident

Digital Recreation from the Scene of the Accident

-

As Featured in Time Compression Magazine: Reverse Engineering Things to Know

As Featured in Time Compression Magazine: Reverse Engineering Things to Know

List of Terrestrial Projects

The Laser Design team has provided 3D scanning services for clients in many industries around the globe. Our 3D scanning engineers work with you to get you the 3D data you need for your project. Below is a list of some of the projects we’ve worked on out in the field.

| Project | Project Overview | Equipment Used | Software Used | Client |

|---|---|---|---|---|

| MSP Airport, St. Paul, MN | Laser scanned airport mechanical rooms and mechanical bays in the terminal. Created a 3D Revit model of the existing structural features, piping, ducts, equipment and conduit. | Leica P30 and FARO Focus 120 | Leica Cyclone, EdgeWise BIM Suite, Autodesk Recap, Autodesk Revit | Mechanical Design Company |

| World Trade Center, New York City | Laser scanning existing structural features and created a 3D model in Revit. | Faro Focus 120 | Faro Scene, Autodesk Recap, Autodesk Revit | Global Designer and Manufacturer |

| Multiple Silicon Valley Tech Company Buildings, Sunnyvale, CA | Laser scanned the interior and exterior of two 9 story office buildings and mechanical areas. Created a 3D model of all the existing MEP, architectural and structural features including the hangers on all of the MEP. | Two Leica P30/40 and FARO Focus 120/330 | Leica Cyclone, EdgeWise BIM Suite, Autodesk Recap, Autodesk Revit | Construction Company |

| Beverage Manufacturing Plants - Arizona, Wisconsin, Minnesota, Illinois, Florida | Laser scanned multiple assembly lines for design purposes and for the future placement of new assembly lines. Added 3D models of designed assembly lines into the point cloud to verify clearances of proposed equipment to monitor impact on the employees and forklifts. | Leica P30 | Leica Cyclone, Autodesk Recap, Autodesk Autocad | Beverage Manufacturer |

See full list of Terrestrial 3D scanning projects

AEC Frequently Asked Questions (FAQ)

Why should my company use 3D scanning?

- No return trips for additional measurements

- Millions or even billions of measurements of everything in the space.

- With our scanners all measurements are accurate to within +/- 1mm to 2mm.

Downstream benefits include:

- Reduction or elimination of field modifications when installing equipment or structural elements when 3D scanning is used in the design phase.

- Documentation of existing conditions for future design/build/maintenance.

- Reduce or eliminate change orders by improved design accuracy.