3D Laser Scanning – Over 30 Years and 25,000 Successful Projects Completed!

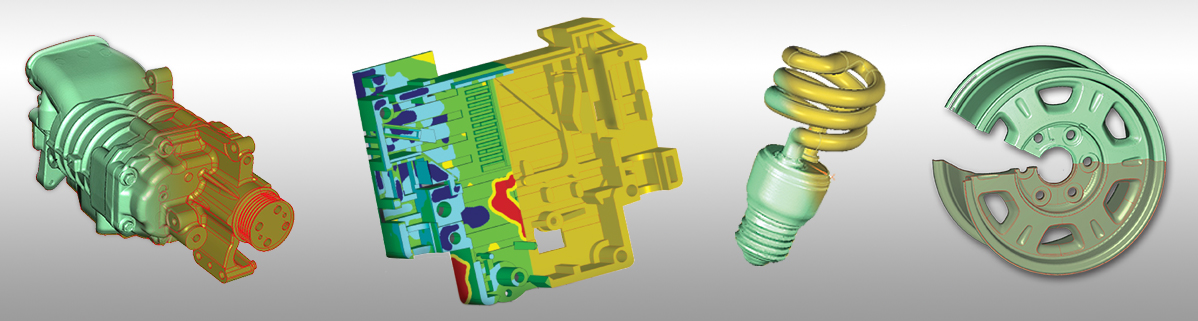

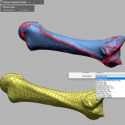

3D scanning, the process of converting physical objects into precise digital models, enables you to quickly and accurately capture your project’s shape and geometries. This process supplies you with a complete digital representation of your part to be used for reverse engineering, quality inspection or at any point of a typical manufacturing cycle. 3D laser scanning technology can provide you with:

- Fast, ultra-accurate results, reducing your time to market (saving you time and money!)

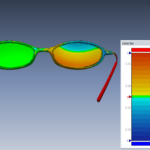

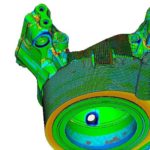

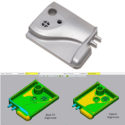

- Complete measurement data of the entire surface of your object, verifying that the as-built part matches your CAD model

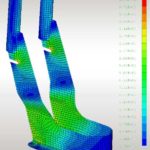

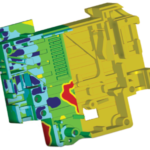

- True CAD models for FEA testing of actual geometry to correct problems before parts go into production

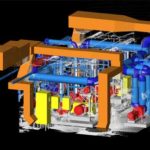

- CAD models to validate tooling, even when no current models exist

- Profile data of the whole part so assemblies can be digitally put together, revealing inaccuracies and interference

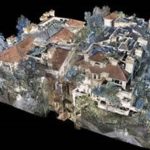

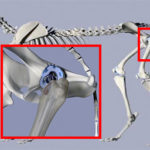

With 30 years of successful 3D scanning projects, Laser Design can scan anything from tiny components to vehicles and even entire buildings. We have locations around the globe and provide customers with unmatched technology and expertise.

Ask a 3D Expert - Microsite

What is 3D Scanning?

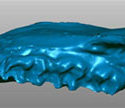

3D Laser Scanning is a non-contact, non-destructive technology that digitally captures the shape of physical objects using a line of laser light. 3D laser scanners create “point clouds” of data from the surface of an object. In other words, 3D laser scanning is a way to capture a physical object’s exact size and shape into the computer world as a digital 3-dimensional representation.

3D laser scanners measure fine details and capture free-form shapes to quickly generate highly accurate point clouds. 3D laser scanning is ideally suited to the measurement and inspection of contoured surfaces and complex geometries which require massive amounts of data for their accurate description and where doing this is impractical with the use of traditional measurement methods or a touch probe.

3D Scanning Photo Gallery

The Laser Design 3D Scanning Team has been busy! Besides a busy lab (that is also ITAR certified) we’ve also been to the World Trade Center, the new U.S. Bank Stadium, Space Needle, Miami Airport, ships in Korea, the Mirage volcano and more! We have the experience and know-how to tackle your next project whether it’s a small hearing aid or an entire ship! Check out our gallery of photos.

3D Scanning Videos

3D Scanning Case Studies

-

High-Precision 3D Scanning using Artec Leo for Custom Race Car Design

High-Precision 3D Scanning using Artec Leo for Custom Race Car Design

-

4 Easy Steps to NURBS Surface Modeling in Geomagic Design X

4 Easy Steps to NURBS Surface Modeling in Geomagic Design X

-

Application Story – 3D Scanning and Projection Mapping

Application Story – 3D Scanning and Projection Mapping

-

3D Scanning Helps Kimberly-Clark Save $500,000

3D Scanning Helps Kimberly-Clark Save $500,000

-

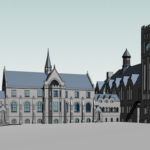

3D Terrestrial Scan of Shattuck St. Mary’s

3D Terrestrial Scan of Shattuck St. Mary’s

-

3D Scanning Provides High-Quality Data of Custom Electric Guitar

3D Scanning Provides High-Quality Data of Custom Electric Guitar

-

3D Scanning Brings Aspiring Car Designer Clay to Life

3D Scanning Brings Aspiring Car Designer Clay to Life

-

3D Scanning at Laser-Light Speed

3D Scanning at Laser-Light Speed

-

3D Scan of Electric Car Opening Doors to the CAD Automotive World

3D Scan of Electric Car Opening Doors to the CAD Automotive World

-

3D Laser Scanning Makes an “Impression” on the Dental Profession

3D Laser Scanning Makes an “Impression” on the Dental Profession

-

3D Laser Scanning Ensures Accuracy and Safety of Free-form Turbine Blades

3D Laser Scanning Ensures Accuracy and Safety of Free-form Turbine Blades

-

1st Virtual: 1:500 Scale Napoleonic Figurines

1st Virtual: 1:500 Scale Napoleonic Figurines

-

29 years of Unusual Laser Scanning Projects

29 years of Unusual Laser Scanning Projects

-

As-Built vs. Design Intent: A Reverse Engineering Dilemma

As-Built vs. Design Intent: A Reverse Engineering Dilemma

-

As Featured in Time Compression Magazine: Reverse Engineering Things to Know

As Featured in Time Compression Magazine: Reverse Engineering Things to Know

-

Compare the Difference: Laser Design Scan Data vs. Industry Average

Compare the Difference: Laser Design Scan Data vs. Industry Average

-

Corvette Engine Cruises With High-Performance Part From 3D Scanning

Corvette Engine Cruises With High-Performance Part From 3D Scanning

-

Lobster Scanning with the Artec Space Spider

Lobster Scanning with the Artec Space Spider

-

Scanning a “Bot” from Mystery Science Theater 3000

Scanning a “Bot” from Mystery Science Theater 3000

-

Dimensionally compare your Physical Part to CAD using CyberOptics XLP Laser Scanner and Geomagic Control X Software

Dimensionally compare your Physical Part to CAD using CyberOptics XLP Laser Scanner and Geomagic Control X Software