Merit Medical sought to gain increased efficiencies in the R&D phase of product development. The Laser Design DeskTom CT scanner expedited time-to-market, improved return on investment and improved operational efficiencies.

Benefit Summary

Benefit Summary

Merit Medical sought to gain increased efficiencies in the R&D phase of product development. The Laser Design DeskTom CT scanner expedited time-to-market, improved return on investment and improved operational efficiencies.

Challenge

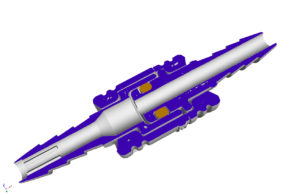

At Merit, every medical device requires a thorough review and testing in the R&D process. Merit experienced one particular testing issue and needed to find a way to solve the problem before the product could be brought to market. An assembly of the product

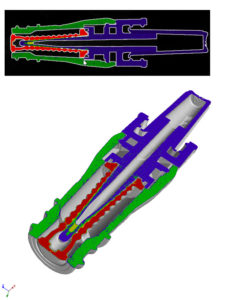

in question utilized an internal o-ring in order to create a fluid-tight seal between two components. However, in this particular instance, bench testing showed that fluid was able to leak around the o-ring under pressure in some of the samples. The root cause of the leakage was unknown as the o-ring is internal to the assembly and couldn’t be seen.

Solution

Solution

The company wanted to find a way to isolate any issues in the R&D design phase and support new product development activities with repeatable and recognizable

methods. After a review of both manual workarounds and competitive product analysis, Merit selected Laser Design’s DeskTom CT scanner, a compact ultra 3D CT (computed tomography) metrology grade, calibrated scanner with an Accuracy of +/- 5µ and High Resolution of 4µ. The X-ray 3D scanning allows for capture of internal and external complex shape geometry for both inspection and reverse engineering capabilities of single components or complex assemblies.

Merit’s use of the DeskTom CT scanner was particularly useful in one R&D application to help identify an issue quickly and with minimal effort. Implementing the solution helped Merit in the following ways:

- Enabled inspection of internal and external surfaces without having to destroy device

- Easily identified root cause of fluid leakage and the fluid leak path around the o-ring internal component

- Accelerated the time to identify the leakage from what can take several months to just a few short weeks

- Accelerated time-to-market after quick and repeatable analysis of device issue

- Saved valuable engineering time and resource allocation

In Merit’s case, the DeskTom CT scanner was able to be used in a 2D x-ray capacity with a specialized setup which allowed pressurization of the assembly with an iodinated contrast solution. The radiopaque dye allowed visualization and video capture of exactly how the o-ring and components were reacting under pressure and clear visualization of the fluid leak path was determined. In addition, leaking and non-leaking assemblies were scanned in 3D and compared using volume graphics software. Both the 2D fluid leak data and 3D scan data allowed Merit to determine the root cause of the fluid leakage in just a few weeks.

In Merit’s case, the DeskTom CT scanner was able to be used in a 2D x-ray capacity with a specialized setup which allowed pressurization of the assembly with an iodinated contrast solution. The radiopaque dye allowed visualization and video capture of exactly how the o-ring and components were reacting under pressure and clear visualization of the fluid leak path was determined. In addition, leaking and non-leaking assemblies were scanned in 3D and compared using volume graphics software. Both the 2D fluid leak data and 3D scan data allowed Merit to determine the root cause of the fluid leakage in just a few weeks.

“Without the DeskTom capability this effort could have taken many months. The solution saved Merit valuable engineering time and resources and our speed to market was significantly accelerated,” said Steven Weir, Vice President, Characterization Technology Unit. Merit Medical Systems.

Merit uses the DeskTom CT Scanner in a number of applications and looks to continue to find ways to maintain its competitive advantage by using this product.

According to Weir, “The system has been extremely helpful in finding interference and issues between parts and assemblies. When you have to dissemble something on the product you likely lose the evidence you are trying to capture. Being able to identify and isolate this information and analyze it real time without taking something apart is critical.”

About Merit Medical Systems, Inc.

Merit Medical Systems, Inc. (NASDAQ:MMSI) is a leading manufacturer and marketer of proprietary disposable devices used primarily in cardiology, radiology and endoscopy. Founded in 1987, Merit Medical Systems, Inc. is engaged in the development, manufacture and distribution of proprietary disposable medical devices used in interventional and diagnostic procedures, particularly in cardiology, radiology and endoscopy. Merit serves hospitals, acute care facilities and clinics worldwide, with a domestic and international sales force totaling approximately 200 individuals. Merit employs approximately 3,900 people worldwide with facilities in South Jordan, Utah; Pearland, Texas; Richmond, Virginia; Malvern, Pennsylvania; Rockland, Massachusetts; Maastricht and Venlo, The Netherlands; Paris, France; Galway, Ireland; Beijing and Hong Kong, China; Tijuana, Mexico; Joinville, Brazil; Markham, Ontario, Canada, and Melbourne, Australia.