Situation

Situation

While structurally strong and economically viable, most plastic parts today suffer from warpage of their otherwise rigid structure over long distances or under differing amounts of pressure. Deflection in laptop lids is a direct effect of the torsion contained in the hinges that keep the lid open.

FAI Materials Testing Laboratory, a materials testing and failure analysis company, needed to quantify the amount of deflection in a laptop lid at various states of openness as part of their Finite Element Analysis (FEA) of the laptop. Realizing the near impossibility of measuring warpage of a part using conventional methods, FAI required a non-contact measurement solution.

I’m very pleased with the work, and the great communication and service, and plan to use 3DScanco for any work of this type in the future.”

Solution

Solution

FAI contacted 3DScanCo – a division of Laser Design Inc. – about solutions to their measurement challenge. Due to the unique quality inspection challenges demanded by the project, a custom inspection strategy was developed and executed. 3DScanCo captured 3D data of the laptop in high detail, capturing not only the laptop, but of surrounding reference geometry. The high detail scans were critical to the success of the inspection as slight variations in warpage are not easily detectable by low resolution scans.

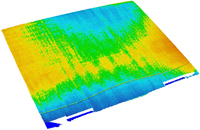

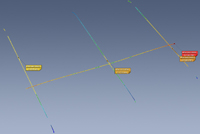

3DScanCo used data acquired of the hinge of the laptop lid as well as surrounding geometry to align and register scans of the laptop lid in a near perfect orientation. The aligned scan data was imported into Rapidform XOV to generate cross-sectional and colormap inspection reports of the laptop lid at various stages of openness.

Results

Results

The inspection reports generated by 3DScanCo quantifed the amount and location of lid deflection under differing amounts of pressure caused by the torsion in the hinges. This warpage information improved FAI’s ability to perform an accurate materials analysis of the laptop lid. 3DScanCo’s inspection solution offered FAI a complete distortion analysis of the laptop lid, which would be virtually impossible without the aid of non-contact 3D scanning as even the slightest contact with the lid would compromise the results.