When you think of “Medicine” what comes to mind? An emergency room full of accident victims? A researcher curing diseases in the developing world? Or just getting rid of your own annoying low-back pain? What you probably don’t think of are high-precision non-contact scanning technologies. However, no matter what your perspective or problem, 3D laser scanning may have had a role in improving some medical process you are familiar with and adding to our overall knowledge of and care for the human body.

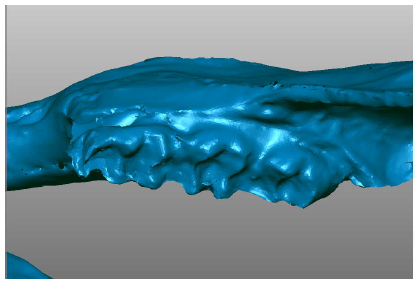

Using 3D scanning in the medical field is becoming more common, and the one thing all medical applications of 3D scanning have in common (which is the greatest challenge as well) is the difficulty of accurately reproducing organic items typically found in medical applications, such as bones, teeth, or other body parts. They are very complex and amorphous shapes with free-form curves. Measuring such forms is nearly impossible and excruciatingly labor-intensive with manual or contact measurement methods.

Using 3D scanning in the medical field is becoming more common, and the one thing all medical applications of 3D scanning have in common (which is the greatest challenge as well) is the difficulty of accurately reproducing organic items typically found in medical applications, such as bones, teeth, or other body parts. They are very complex and amorphous shapes with free-form curves. Measuring such forms is nearly impossible and excruciatingly labor-intensive with manual or contact measurement methods.

However when it comes to amorphous shapes, non-contact 3D laser scanning is just what the doctor ordered. Laser scanners can capture an object’s complete geometry, digitally reproducing a highly accurate model in a very short time. 3D laser scanning is extremely fast, accurate, and thorough, and it is able to digitize the entire topography of whatever shape it sees. If the internal geometry of a part is needed, then computed tomography (CT) scanning fits the bill with its superb exactness, ability to “see” inside parts, and non-destructive nature.

These types of non-contact scanning result in precisely digitized “point cloud” versions of the shape from which CAD models are made. The CAD model can be used to replicate, manufacture, fit, assemble, animate, test, demonstrate, simulate, and document the object for a virtually infinite array of innovative medical applications.

Laser Design, Inc., a leading supplier of 3D laser scanning systems for more than 20 years has frequently been asked to provide a scanning system specifically designed for customers with medical applications. GKS Inspection Services, Laser Design’s engineering services division, has regularly been called upon to perform scans for medical device or research organizations as well. The company realized that many of these requests had certain aspects, such as required accuracies, scan densities, and part size in common. The newly developed high-speed, high-precision Surveyor WS-2030 scanning system is especially well suited to this market.

Laser Design, Inc., a leading supplier of 3D laser scanning systems for more than 20 years has frequently been asked to provide a scanning system specifically designed for customers with medical applications. GKS Inspection Services, Laser Design’s engineering services division, has regularly been called upon to perform scans for medical device or research organizations as well. The company realized that many of these requests had certain aspects, such as required accuracies, scan densities, and part size in common. The newly developed high-speed, high-precision Surveyor WS-2030 scanning system is especially well suited to this market.

The Surveyor 3D laser scanning system’s patented laser probe technology dramatically reduces scanning time by collecting data significantly faster and more accurately than other technologies. The laser scanning system projects a line of laser light onto surfaces while cameras continuously triangulate the changing distance and profile of the laser line as it sweeps along. The problem of missing data on an irregularly shaped surface is greatly reduced or eliminated. The system measures fine details and captures complex free-form geometry so that the object can be exactly replicated digitally. Laser scanners measure articles quickly, picking up tens of thousands of points per second, and generating huge numbers of data points without the need for templates or fixtures.

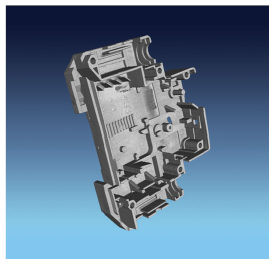

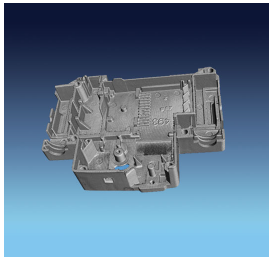

As medical devices have become more complex and designed with more internal electronic parts, Laser Design / GKS has acquired the capability to perform CT scans as well. It is an ideal measurement method for inspecting extremely complex parts and assemblies too difficult to measure with conventional touch probe or line-of-sight vision-based scanning technologies. The speed and precision make CT scanning a viable option for non-destructive testing of production line and critical components.

The Many Applications of Non-Contact 3D Scanning

1. Device Development

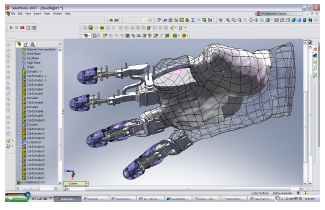

One of the most prevalent uses for non-contact 3D laser scanning is in creating new life- saving and life-enhancing devices, such as prosthetics. GKS has scanned various body parts for many different applications; in one such project small hand casts were scanned in order to create fully functional finger prosthetic devices.

One of the most prevalent uses for non-contact 3D laser scanning is in creating new life- saving and life-enhancing devices, such as prosthetics. GKS has scanned various body parts for many different applications; in one such project small hand casts were scanned in order to create fully functional finger prosthetic devices.

The devices were body-powered, light-weight, and allowed the users to regain complete control of the flexion and extension movements of an artificial finger. 3D digital CAD model files were needed to manufacture custom prostheses more cost effectively for a larger market.

According to the prosthesis company’s owner, “Compared to manually measuring, the process of laser scanning cut 60% off the amount of time to make enough accurate measurements of the casts to create a CAD model. With over 600 different variations of each finger-hand configuration, plus six different hand sizes, getting the correct measurements is incredibly labor intensive. I can’t think of an alternative to 3D laser scanning that would provide similar results. The geometry is too amorphous to capture without laser scanning.”

GKS delivered highly accurate solid models (±.002” or .05 mm) since they are created directly from scan data. To achieve a model of free-form shapes with this kind of accuracy is impossible by any other means. With such an accurate definition of the actual hand, the company can fit a prosthetic device perfectly.

GKS delivered highly accurate solid models (±.002” or .05 mm) since they are created directly from scan data. To achieve a model of free-form shapes with this kind of accuracy is impossible by any other means. With such an accurate definition of the actual hand, the company can fit a prosthetic device perfectly.

In the past, hand prostheses relied heavily on a fabricator’s artistic ability. They were visually realistic but not functional with articulation and mobility. Today’s prostheses restore not only the look of the hand, but the functionas well. Laser scanning is a technology that can capture the fine details of the hand to make the prosthesis fit comfortably and function perfectly.

2. Device Fit

When the fit of a device is critical to its function, 3D laser scanning provides highly reliable data. For example, GKS was asked to scan a new mask-like breathing device used to prevent a sleeping disorder. A good seal on the user’s face was critical to the device’s successful function. The mask’s parts were made of different materials based on their purpose in the assembly The part that made contact with the face was soft and pliable so it would be comfortable and stay in place, while the parts that delivered a stream of air were hard plastic. Since laser scanning is non-contact, it was able to digitize all the parts of the unit, even the soft ones, without compressing and distorting the shapes. The CAD model was accurate and useful to the engineers so they could make modifications and test the design. The manufacturer can also use laser scanning to verify consistent results of the molded products.

3. Rapid Manufacturing

An early adopter of Laser Design’s laser scanning systems was the hearing aid industry. A fully automated laser scanning system was created to scan the ear impressions of hearing aid users. The ear impressions, created in the field by audiologists, are sent to the hearing aid maker who in the past had manufactured the final product using a labor-intensive manual process.

The LDI laser scanning system set automatic scan parameters since the ear impressions’ size is quite uniform and then used specialized software to process the scan data of the impressions to make the digital model of the ear shell in a fraction of the time. The model is used to manufacture the ear shell for the hearing aid on a rapid prototyping (SLA or FDM) machine, in effect “mass customizing” the products.

This non-contact process significantly improved the fit of the aids inside the ear canal. A better, more comfortable fit resulting from automated laser scanning reduced the chronically high return rates for the devices, which saved the hearing aid company many thousands of dollars every day.

4. Device Redesign

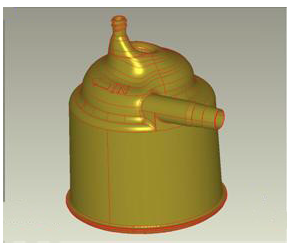

A GKS client who manufactures medical devices, wanted to modify an existing model of a plastic resin heart to demonstrate a new cardiac device product. The company needed modifications on the unit to fit the new device and then to be able to manipulate it in the CAD software to create the demonstration piece. The design engineer noted that the heart model was a “tricky, amorphous shape which is difficult to scan with a contact process.” It also had an irregular internal, partially open cavity, which needed to be very accurate since that is where the new device would be inserted.

A GKS client who manufactures medical devices, wanted to modify an existing model of a plastic resin heart to demonstrate a new cardiac device product. The company needed modifications on the unit to fit the new device and then to be able to manipulate it in the CAD software to create the demonstration piece. The design engineer noted that the heart model was a “tricky, amorphous shape which is difficult to scan with a contact process.” It also had an irregular internal, partially open cavity, which needed to be very accurate since that is where the new device would be inserted.

The most difficult challenge in scanning the heart model was the many small venous features. Larry Carlberg, GKS Service Bureau Manager, explained, “We received the resin model with the unnecessary items removed, but the intricate small features were still present. The ability to model the many small features and maintain a reasonable budget is a combination of the experience level of our modelers and our software’s advanced tools.”

The modeling process demanded attention to the tiny surface abnormalities. Otherwise the model would generate undesirable ripples on the surfaces. The surface model GKS generated had outstanding replication of the plastic model that could not have been achieved by conventional modeling packages.

Once imported into CAD, the design company was able to add the necessary features. Then the data was exported to create a rapid prototype SLA model on which they could demonstrate their new cardiac device product to their customers. The improved RP heart model functioned perfectly with the new device.

Once imported into CAD, the design company was able to add the necessary features. Then the data was exported to create a rapid prototype SLA model on which they could demonstrate their new cardiac device product to their customers. The improved RP heart model functioned perfectly with the new device.

5. Inspection and Validation of Device Redesign

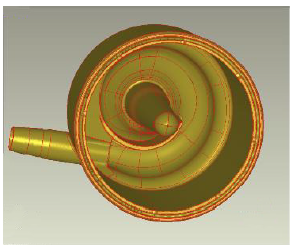

Laser scanning helped a medical device manufacturer validate the design of a new venous filter by ensuring that the computer aided design (CAD) geometry used as the starting point matched a molded arterial filter part that had been proven safe in the field. This can be done easily by scanning the existing flow path geometry and extracting IGES curves from the triangulated point cloud in the form of an STL file for use as a template in creating the new filter geometry. Engineers wanted to take advantage of the effective arterial filter model by duplicating much of the flow path geometry in the new venous filters.

But the engineers realized that the geometry of the flow path was so complex that they could not be sure that it matched the original CAD model without stringent inspection. They thought about inspecting the part with a coordinate measuring machine (CMM) but realized that the number of points that would be required to fully validate the 3D surfaces was far more than it would be practical to capture using one-point-at-a-time contact methods.

But the engineers realized that the geometry of the flow path was so complex that they could not be sure that it matched the original CAD model without stringent inspection. They thought about inspecting the part with a coordinate measuring machine (CMM) but realized that the number of points that would be required to fully validate the 3D surfaces was far more than it would be practical to capture using one-point-at-a-time contact methods.

Fortunately, they discovered that laser scanning technology presented a viable alternative. GKS Inspection Services was able to provide the high accuracy and fast turnaround the company needed. The laser scanning process generated a point cloud with the millions of points to accurately define the complex surface geometry of the part. GKS then created a graphical comparison of the manufactured part with the CAD model, while coding differences between the two in colors that indicate the magnitude of the variation from the design intent. Being able to see the differences in 3D make it much easier and faster to compare the parts. The engineers were able to instantly visualize the differences between the model and the molded part.

Based on these laser scans, engineers made a number of modifications to their CAD model to match it more perfectly to the actual as-built part. The entire process of scanning the part and developing the difference map took less than two days and the

cost for the inspection process was minimal. Compared to conventional CMM touch probe-based measurement, the turnaround for laser scanning was much faster and yielded highly accurate and complete results. This application demonstrates that laser scanning provides a fast, a  ccurate and economical method of validating the geometry of even the most complex geometries.

ccurate and economical method of validating the geometry of even the most complex geometries.

6. Replacement “Parts” Fabrication

The advanced technology of computed tomography (CT) scanning can be used to recreate bones and other structures in living organisms, including people, because it is non-destructive and captures internal geometry as well as surface profiles. For example, a patient had severe TMJ which wore out the cartilage of the mandible and was causing pain in the joint. The digital STL data from the CT scan done on the person’s oral cavity was used in a SL rapid prototype system to create an accurate replica of the mandible. With the precise replica, a replacement “bone” could be built with a special synthetic material and then surgically implanted in the patient’s jaw.

Once again, non-contact scanning faithfully captured the entire shape of the amorphous organic structure and cavities from a human body. CAD models from such scans can be used in manufacturing to create any type of joint, tissue, or other structure within modern medicine’s purview.

7. Research Purposes

3D laser scanning can be used to enlarge the archive of documented fossils for research purposes. With plentiful scan data records, meaningful compilations and analyses can be conducted. CT scanning can be used on current patients to document conditions, progress, and problems in patient care, studies, and clinical trials. Digital documentation reduces the need for storage space as well as waste from hard-copy records.

3D laser scanning can be used to enlarge the archive of documented fossils for research purposes. With plentiful scan data records, meaningful compilations and analyses can be conducted. CT scanning can be used on current patients to document conditions, progress, and problems in patient care, studies, and clinical trials. Digital documentation reduces the need for storage space as well as waste from hard-copy records.

If a condition or disease is prevalent within a population, cures or preventative measures may be found by modeling the characteristics or abnormalities found in the digital files. Data mining may also uncover unexpected or hidden trends and similarities within the groups studied. GKS has performed many scans on fossil bones and teeth to create research databases for anthropologists and archaeologists as well.

8. Training, Simulations, and Animations

With the advancement of computer-aided instruction (CAI) in the medical field, totally accurate anatomical models are essential. To train doctors on specific procedures , many body parts have been scanned in order to create lifelike simulations and animations depicting procedures and typical treatments. The realism of the images obtained from the scan data is astounding.

Also, medical devices can be digitized and procedures for fitting, assembly, and implanting them produced for teaching and training. Demonstrations are easily put together with the scan files, and even FEA studies can be run on the physical properties of the materials and devices.

To preserve and transmit knowledge to a wider base of practitioners, an anatomical library or database (of structures such as the spine, teeth, ears, hip joints, etc.) can be compiled for such training purposes, making life-saving surgeries, routine medical procedures, and other manipulations safer for doctors and patients alike.

9. Reverse Engineering a Part with no CAD Data

As with any type of physical part that is manufactured, sometimes no CAD data exists for a medical device. The part may be so old that it was originally manufactured in the days before digital models, or the CAD data may have been lost in time or when a company was sold and products specifications changed hands. In any case, today’s manufacturing processes, including those that make advanced medical products, require a CAD model for tooling, molds, inspections of parts, and product designs or enhancements.

Laser scanning is the fastest, most accurate, and automated way to acquire 3D digital data and a CAD model of a part’s geometry when none is available. Re-creating complex free-form shapes is non-contact measurement’s best application. Both the positive and the negative version of a scanned part are easy to create, so no matter what part of a manufacturing process is lacking, 3D laser scanning can provide the correct type of data file. Also, new features and updates can be integrated into old parts once the modeling is accomplished.

Accurate, Fast 3D Scanning Technologies Provide Many Benefits

The rapid advancement in medical technology is largely been due to the breadth of research in the field and vast improvements in measuring and manufacturing processes. Non-contact 3D scanning technologies are playing an important role in many of the revolutionary advances in device development, fit, redesign, and validation, as well as actual re-creation of organic parts with complex, free-form shapes. As 3D scanning technologies’ acceptance and use increase, even more new applications will be developed that will boost accuracy, speed, and cost-effectiveness of treatments. Some day soon, one of these advanced scanning technologies could save accident victims, people suffering from serious conditions, and even your aching back!