The quality team at Versatile Mold, led by Albert Whitaker, Director of Quality and Trevor Martin, Quality Technician, were challenged to figure out how to distinguish Versatile Mold from their competitors. They felt there was no better way than to improve their quality while shortening the design and qualification cycle. Determining that the earlier in a project errors might be detected led them to a very innovative process. They would verify the correctness of an injection molding tool BEFORE any steel was cut.

The quality team at Versatile Mold, led by Albert Whitaker, Director of Quality and Trevor Martin, Quality Technician, were challenged to figure out how to distinguish Versatile Mold from their competitors. They felt there was no better way than to improve their quality while shortening the design and qualification cycle. Determining that the earlier in a project errors might be detected led them to a very innovative process. They would verify the correctness of an injection molding tool BEFORE any steel was cut.

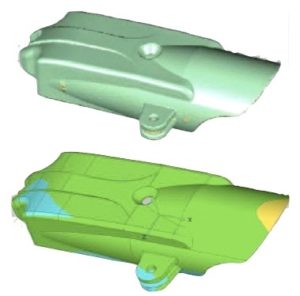

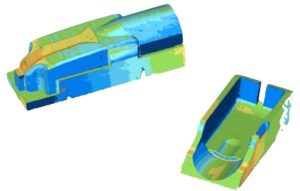

Versatile Mold uses a process known as EDM which very quickly burns into pre-hardened steel, allowing for very precise, difficult shapes to be cut into the core and cavity of a tool. If the carbon electrodes are correct, the tool will be correct. Verifying the electrodes before wasting a $10,000 block of steel seemed to be a perfect method to guarantee quality before any chips flew.

One advantage of using this process was to assure that in the case of multiple cavities, each set of electrodes matches.”

Using a Laser Design SURVEYOR- 3D Laser Scanning System (accurate to 0.011mm), each carbon electrode is scanned and compared with the perfect CAD model, complete with exacting burn allowance, draft and all features. This inspection also is ideal for First Article Inspections of parts from the tool to speed up time to market.

One advantage of using this process was to assure that in the case of multiple cavities, each set of electrodes matches. Martin simply scans each set and compares the two scans using Geomagic Control Inspection software. By using Geomagic – Reverse Engineering software, changes in the tooling can also be done quickly, with a modified CAD model of the changed electrode complete and verified.

One advantage of using this process was to assure that in the case of multiple cavities, each set of electrodes matches. Martin simply scans each set and compares the two scans using Geomagic Control Inspection software. By using Geomagic – Reverse Engineering software, changes in the tooling can also be done quickly, with a modified CAD model of the changed electrode complete and verified.

Versatile Mold, located in little Rutledge, GA, between Augusta and Atlanta, a town of some 700 (est. 1845) is clearly a center of modern day 3D Imaging technology innovation using Laser Design 3D scanning systems and Martin and Whitaker were able to succeed in the challenge set before them of distinguishing the company from it’s competitors.

About Versatile Mold

Versatile Mold is a full-service molding facility capable of providing support through all phases of the molding process, from design to mold sampling with expertise in engineering thermoset, thermoplastic injection, compression, injection-compression, and transfer, as well as general machining and refurbishment.