Situation

Situation

BSCI Energy Impact Systems is a leader in the development and research of foam safety components and has pioneered innovations that have set the industry standard in professional racing. BSCI’s successes are driven by their understanding of the importance of properly designed and functioning padding inside the car – padding that helps protect drivers from the tremendous forces applied during a crash.

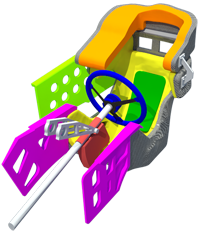

Top drivers from around the world come to BSCI for custom-fit seats that perfectly match the shape of their bodies. In order to manufacture smooth seating using BSCI’s preferred and proven materials, a digital model of the physical proportions of one’s unique, organic shape must first be created.

Everything went great with the last scan – you guys sure are good at what you do… I really have been happy with your outstanding work and service.”

Solution

Solution

BSCI contacted 3DScanCo — a division of Laser Design Inc — for guidance with their manufacturing challenges. Under tight time-constraints, BSCI shipped a seat model to 3DScanCo to have its surface measurements captured with a high resolution 3D laser scanner. BSCI needed the finished model to be both accurate and smooth, requiring 3DScanCo to clean and optimize the data while preserving the high detail areas around the edges.

3DScanCo used the optimized scan data to fit CAD data to the freeform surfaces which accurately captured the shape and contours of the seat – essentially the negative of the subject’s body. The final step was optimizing the organic, yet fully mathematical, model for manufacturing to reduce BSCI’s machine time.

Results

Results

3DScanCo’s services yielded an ideal solution for BSCI to obtain and create digital 3D data of custom-molded seats. The CAD data provides BSCI the ability to quickly manufacture new and/or replacement seats. Due to the demands of the racing industry, 3DScanCo often receives, scans, models and ships back what is the only copy of a particular seat with a typical turnaround time of 1-2 days.

BSCI continues to work with 3DScanCo on new designs and have completed dozens of projects together creating seats and headrests that improve the comfort and safety of drivers in NASCAR®, NHRA®, Grand Am Daytona Prototype and Ferrari Challenge series race teams.