Situation

Situation

Medical training programs are the cornerstone of successful medical practice. Medical Education Technologies Inc. (METI), a developer of medical training products, lost its only supplier of the PediaSIM® airway, leaving them with physical models, but no CAD data and no way to manufacture them. Not wanting to completely redevelop the product, METI sought to reverse engineer CAD data from the limited number of physical parts they had left.

METI made several attempts to reverse engineer the design. However, the internal features seemed to be impossible to capture with conventional scanning techniques. The detail of the hollow rubber esophagus and mouth would need to be captured from the inside out while preserving the original shape.

We were impressed with you and your team, your depth of knowledge in 3D scanning, product development, and how you were consistently on time and on budget.”

Solution

Solution

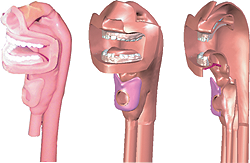

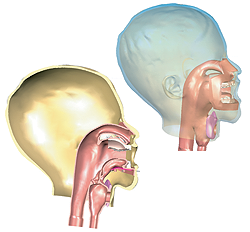

The first challenge posed to 3DScanCo — a division of Laser Design Inc — was capturing the internal features. 3DScanCo’s breakthrough development of Soft Internal Non-Contact Scanning (SINCS™) allowed 3DScanCo to effectively see through the part. Using a special new compound (SINCOR™), 3DScanCo captured and scanned the internal features with the Konica Minolta VIVID 9i. After scanning the external features, the two data sets were combined to generate a complete scan model. 3DScanCo reverse engineered this scan data to create CAD data, which fully captured the organic detail of both the external and internal features.

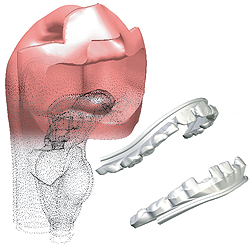

The second challenge was to design a rubber head and dental region and integrate them with the esophagus and mouth. Scan data of an actual child’s face was reverse engineered to create CAD data, which was redesigned to fit perfectly with the esophagus and mouth. 3DScanCo also reverse engineered teeth made from dental impressions, which were sized and fit to the mouth.

Results

Results

3DScanCo’s breakthrough development of the SINCS™ system enabled 3DScanCo to perform scanning services that would have otherwise been impossible. By using 3D scanning rather than redesigning the product, METI was able to significantly shorten the design process down to three months. The 3D scanning solution resulted in PediaSIM® retaining all the organic details present in the original.

3DScanCo’s reverse engineering services enabled METI to manufacture an enhanced version of the ultra-realistic PediaSIM®, which will be used to train the next generation of doctors, physicians, and medical professionals around the globe.