Situation

Situation

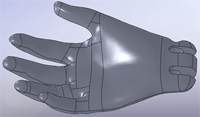

Denton ATD Inc, a leading provider of Anthromorphic Test Devices (ATDs), needed to update the shape and features of many of their existing ATDs. Because the parts were designed and manufactured many years ago, most lacked any CAD data. In order for Denton to update their manufacturing and design process, they would need CAD data of all the unique parts that comprise each ATD.

We look forward to working with 3DScanCo for any type of 3D scanning work. They have earned our trust, the highest praise.”

Solution

Solution

Denton contracted 3DScanCo to scan and reverse engineer accurate CAD data of over 20 unique parts within two weeks of their arrival at 3DScanCo’s Engineering Service Center. 3DScanCo used a high accuracy 3D laser scanner to capture the shape, details and bolt-hole locations of each part, which was then reverse engineered into native Autodesk Inventor CAD models. The resulting CAD data perfectly matched both the shape and design intent of the parts.

Results

Results

3DScanCo’s scanning and reverse engineering services provided Denton with CAD data for nearly every manufactured component of the ATDs. Most critical to the use of the CAD data were the bolt hole locations, which were modeled in their entirely, ensuring that the parts fit together perfectly.

In addition to solving manufacturing challenges, the native Inventor data enables Denton to make modifications to an existing line of ATDs. Denton continues to trust in 3DScanCo’s scanning and reverse engineering services with followup service projects of the same nature.