Situation

Situation

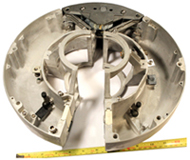

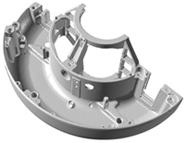

Microprocessor Designs, a product design and development company, needed to obtain CAD data of a desktop-sized ‘donut’ consisting of four sections. The complex sections contain numerous bolt-holes and features which are critical to the function and fit of the part. In order to obtain CAD data, Microprocessor Designs would need to reverse engineer their existing physical part to match the design intent.

I’m very pleased with the work, and the great communication and service, and plan to use 3DScanco for any work of this type in the future.”

Solution

Solution

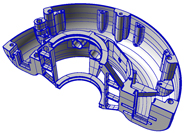

Microprocessor Designs contracted 3DScanCo -a division of Laser Design Inc. – to reverse engineer the four sections of the donut. 3DScanCo used a high accuracy 3D Scanner to capture the surface data and bolt-hole locations of the parts. The scan data was then reverse engineered into fully parametric SolidWorks models that accurately represented the parts inherent design intent.

Results

Results

“I just wanted to let you know that the files that your team scanned and prepared for us on our ‘donut’ shaped shell parts are excellent. I’m most impressed with the native SolidWorks files – all of the holes and surfaces are accurate, and they’re a breeze to work with in SolidWorks. I’m very pleased with the work, and the great communication and service, and plan to use 3DScanco for any work of this type in the future.”