“We at Laser Design know that laser scanning technologies have advanced tremendously in the last several years,” said Larry Carlberg, Laser Design Service Bureau Manager. “Manufacturers who have adopted them now have many choices to make when they want to digitize their parts: what accuracies are necessary for the application, how quickly they need the data, and what format the scan files are. And they have to decide whether they can accomplish optimal scanning results themselves or if they need expert assistance.”

“We at Laser Design know that laser scanning technologies have advanced tremendously in the last several years,” said Larry Carlberg, Laser Design Service Bureau Manager. “Manufacturers who have adopted them now have many choices to make when they want to digitize their parts: what accuracies are necessary for the application, how quickly they need the data, and what format the scan files are. And they have to decide whether they can accomplish optimal scanning results themselves or if they need expert assistance.”

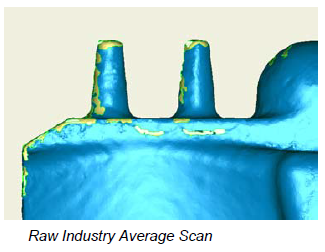

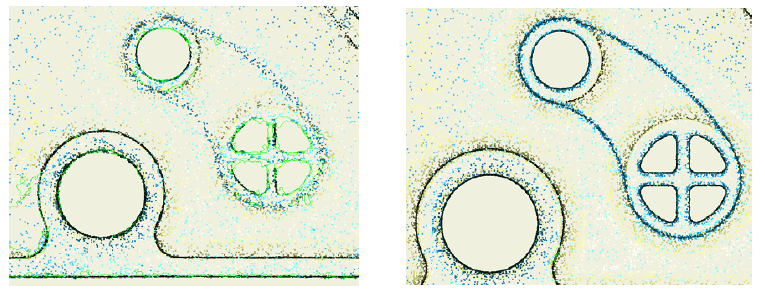

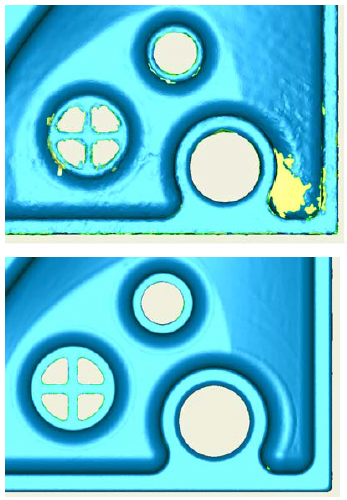

Carlberg continued, “Sometimes companies try to minimize costs by using a very inexpensive service bureau or by scanning with a low-end system themselves. Needless to say, as we hear from them after the fact, the results are always commensurate with the lack of quality of the system and the lack of experience of the person performing the scan—very limited.” Saving a few bucks at the outset by scrimping on the most important quality elements of high-precision 3D laser scanning usually adds hundreds, if not thousands of dollars at the end of the process to obtain acceptable data.

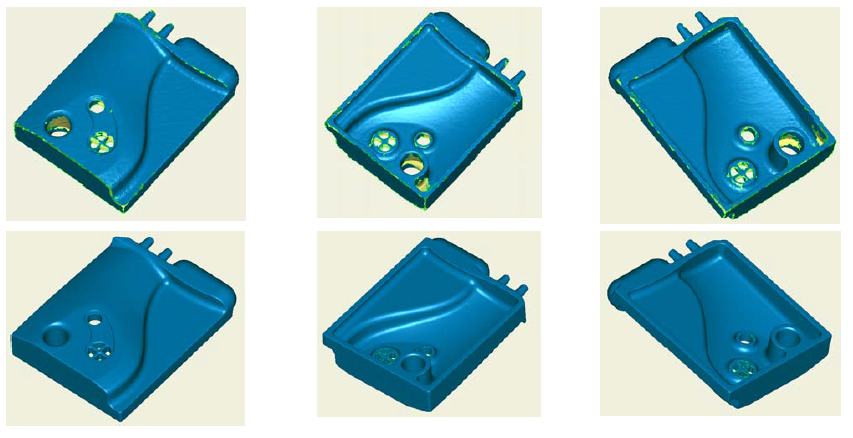

The ever expanding communications industry is just one example where high quality and consistent results are essential to satisfy new product demands. Over the years Laser Design has scanned many electronic devices with complex profiles as a critical step in the development process for various communications-related products on the fast track. Laser Design’s experience and quality in this arena are unparalleled and the results are guaranteed.

The ever expanding communications industry is just one example where high quality and consistent results are essential to satisfy new product demands. Over the years Laser Design has scanned many electronic devices with complex profiles as a critical step in the development process for various communications-related products on the fast track. Laser Design’s experience and quality in this arena are unparalleled and the results are guaranteed.

Scanning options abound and sometimes misguided cost-cutting measures force companies to try using a lower-priced service bureau. Unfortunately, many service bureaus can no provide the desired output atthe required accuracies and companies who use them often end up sending the models to Laser Design for conversion anyway, wasting valuable time and money. Carlberg commented, “Coming in late in the process creates a problem because we don’t have the model history information at the start. We have to create our own CAD models before we can do the conversions.” The required conversions can take much longer leading to missed opportunities in the market place.

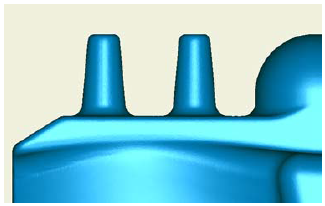

Avoiding delays may cause management to try another venue for obtaining the required models: scanning themselves with a low-end scanner. However, they often find that the data produced is unusable. Again, with regularity, companies end up contacting Laser Design to perform their fast, high-quality scans on complex-shaped devices. When Laser Design has control over the entire scanning process, scanning, smoothing, and modeling, the turnaround time is significantly reduced, usually only a couple of business days.

Avoiding delays may cause management to try another venue for obtaining the required models: scanning themselves with a low-end scanner. However, they often find that the data produced is unusable. Again, with regularity, companies end up contacting Laser Design to perform their fast, high-quality scans on complex-shaped devices. When Laser Design has control over the entire scanning process, scanning, smoothing, and modeling, the turnaround time is significantly reduced, usually only a couple of business days.

Fortunately, some companies have a better understanding of the laser scanning process and even own their own systems. They know that when they have a highly complex project that requires ultra-precise, fast results, the successful solution may be to use Laser Design’s scanning services rather than to go it alone. Laser Design possesses both the technology and the technical know-how and experience to ensure that every project they perform is done well and to the customer’s complete satisfaction.

“One thing I have learned,” continued Carlberg, “is that many companies have tried low-end scanners and found that they are not accurate enough for highly complex surfaces. So after their unsuccessful scanning experience, we are able to meet and exceed their needs for all of their challenging projects.”