Situation

Situation

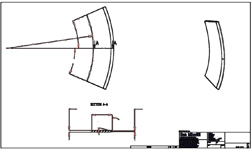

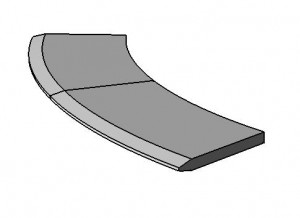

CertainTeed, a complete building products manufacture, needed to reverse engineer existing roofing tile cutters. The cutters are currently in use by CertainTeed, however no CAD model of the physical parts existed. In order to reproduce the cutters, certain needed to obtain CAD files and 2D Drawings of their parts.

difficult without 3d scanning because the roofing tile cutters had a complex cross section and varying edge angles.

The main reasons I will try and use 3DScanCo in the future is your technical expertise and knowledge of the scanning hardware and software.”

Solution

CertainTeed contracted 3DScanCo – a division of Laser Design Inc – to scan and reverse engineer their existing roofing tile cutters. 3DScanCo used high resolution 3d scan data to create accurate CAD models of the roofing  tile cutters. Once the physical parts were back in CAD they can be used for a variety of applications including machining, rapid prototyping, computer aided engineering analysis, or to just create 2D drawings.

tile cutters. Once the physical parts were back in CAD they can be used for a variety of applications including machining, rapid prototyping, computer aided engineering analysis, or to just create 2D drawings.

Results

3DScanCo was able to succesfully use the CAD model to create 2D drawings. CertainTeed was then able to use the 2D drawings and CAD file to manufacture new roofing tile cutters. This process would have been extremely difficult without 3d scanning because the roofing tile cutters had a complex cross section and varying edge angles.