The quality team at Versatile Mold, led by Albert Whitaker, Director of Quality and Trevor Martin, Quality Technician, were challenged to figure out how to distinguish Versatile Mold from their competitors. They felt there was no better way than to improve their quality while shortening the design and qualification cycle. Determining that the earlier in a project errors might be detected led them to a very innovative process. They would verify the correctness of an injection molding tool BEFORE any

Quick Case Study- Outboard Motor

John purchased a miniature motorized “toy” outboard motor from Ebay and wanted to reproduce using a more substantial motor/gearing set up for R/C use. The outboard is 6 inches tall and the two halves can separate to easily remove the internal components. He contacted an RP company but quickly realized he would need a 3D Solidworks model first. Laser Design Services scanned the outboard motor for a RC device and gave him CAD models and ABS prototype part in about 8

Verifying Assemblies Using CT Scans and Geomagic

Rus Emerick, Global Process Owner for 3D Imaging at Schneider Electric, spends a lot of time thinking about tolerances. Starting with tolerances of individual parts, his brain moves swiftly on to the effect of chains of tolerances that, once you get to 4, 5 or more parts in an assembly, could cumulatively affect the reliability of the products being made at any of their manufacturing and design sites in 22 countries around the world. But how can the consistency of

Long-Range Scanning Busts Crunch-Time Large-Scale Project Deadline

Company: This southeastern U.S. company provides general contracting, construction management, and design/build services for larger commercial, industrial, and institutional projects. Challenge: With a deadline of just three weeks looming, new material-conveying systems had to be installed into existing structures at nine far-flung sites. The modifications would expand capabilities to new structures while avoiding interferences with old ones. The scale of the entire project was huge due to the large sizes of the onsite locations, the distance between locations, and the

New Tricks for Old Dogs: Veterinary Surgical Hip Replacement

Company: The well established East Coast company designs, develops, and manufactures state-of-the-art veterinary orthopedic implants for small animals. It holds patents on several designs addressing clinical needs in the canine hip, knee, and elbow. Standards for articulating surfaces of implants which meet or exceed those specified for human implants are maintained in all its products. The company is represented in over 95% of the US Veterinary Teaching Universities, selected international universities, and specialty clinics all over the world. Challenge: With

Laser Design Engineering Services Customer, Sbyke® Wins Two Prestigious Awards

Laser Design is proud to announce that one of their engineering services customers, Sbyke USA, LLC, has won awards for its outstanding patented rear-steer kick scooter from both Popular Science and Parenting magazines. Receiving top honors in Popular Science’s “Wheel Wars” competition and Parenting’s “Best in Play,” the sbyke® was also an instant hit at the American International Toy Fair in New York, 2011. Sbyke co-founders Steve and Bart Wilson wanted to use the most advanced technologies to design, test,

Drive Like the Pros: Racing Teams and Aficionados Sharpen Skills and Improve Performance with Advanced Full-Motion Simulator

Company: Founded in early 2007 on the West Coast, this high-tech engineering firm has revolutionized the design and manufacture of advanced full-motion personal racing simulation equipment. Its highly specialized products are used not only in professional racing team training and testing environments, but also in private homes, motoring clubs, racing schools, and specialized retail settings. Each simulator is individually assembled, tested, installed, and fully supported. Challenge: The company designed a mounting system for a specific racing seat in a new

Loud and Clear: 3D Scanning Perfectly Reproduces Miniaturized Printed Circuit Boards for Microphone Products

Company: The southern U.S. company manufactures voice products for mic’ing people on stage, TV, and movie production. Challenge: Complex electronics are getting smaller all the time. In the case of microphones, smaller versions for performers mean less interference with their ability to move and act as the role demands. The company wanted to further miniaturize their microphone products, which required developing smaller printed circuit boards (PCB) and redesigning their housings. The housings had to be the smallest possible size to

Scanning Hand Made Sculptures

Situation Scaling hand made sculptures is extremely difficult, time consuming, and sometimes impossible. Urbana needed to create a master pattern of their hand made sculpture for plaster casting. Since the plaster would shrink after production a scale factor up from the originally had to be used, but to do this without scanning would mean creating several very similar parts for the various production methods. 3DScanCo has remained in contact with ARINC and worked hard to give us a deliverable in

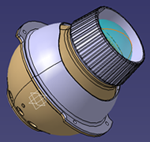

Aircraft Lightbulb Assembly

Situation The CAD Workshop, a Dassault Systemes training company, needed to obtain CAD data of an aircraft lightbulb unit, which consists of an assembly of 9 separate parts. Before creating a CATIA assembly model, 3DScanCo’s – a division of Laser Design Inc. – challenge was in correctly orienting and aligning the 9 sets of scan data to create an accurate representation of the entire lightbulb unit. I have been well pleased with outcomes from 3DScanCo. Very professional and extremely knowledgeable

Team Technologies Requires Scanning Services

Situation Blister packs and other thermoformed parts often present problems to design engineers. Frequently there are numerous complex shapes, blends, and radii. Team Technologies, a leading manufacturer in Dental, Medical, Cosmetic, and Industrial Products, had two thermoformed blister packs. Team Technologies needed to manufacture these parts but had no way of creating the molds. I feel you have the right combination of creative engineering balanced with a well grounded foundation of what it takes to commercialize a new technology like

Ancient Chinese Dagger Is Priceless

Situation Collectors of ancient artifacts know that while rare and sometimes extremely valuable, the preservation and maintenance of relics of the past is of the upmost importance. While restoration of such antiquities can extend their life, the chemical reactions taking place within their ancient materials mean that decay and deterioration is unavoidable. Priceless Past, a distributor and service provider of ancient artifacts, had acquired a Bronze dagger dating back to the 5th century BCE from the Qiang minority in ancient

Panoramic Inc Packaging Project

Situation Panoramic Inc., a designer and manufacturer of custom thermoformed plastic packaging products, needed to reverse engineer existing paper packaging to create new plastic packaging. The existing paper packaging held consumer products, no CAD of the consumer products or the existing packaging was available for Panoramic to design new plastic packaging from. Panaromic needed to quickly create a CAD model so they could cut new thermoform tooling. We look forward to working with 3DScanCo for any type of 3D scanning

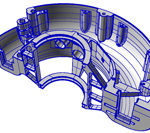

Desktop-Sized Donut Scanning Project

Situation Microprocessor Designs, a product design and development company, needed to obtain CAD data of a desktop-sized ‘donut’ consisting of four sections. The complex sections contain numerous bolt-holes and features which are critical to the function and fit of the part. In order to obtain CAD data, Microprocessor Designs would need to reverse engineer their existing physical part to match the design intent. I’m very pleased with the work, and the great communication and service, and plan to use 3DScanco

Steel Machine Parts Receive Remodel

Situation J.C. Steele & Sons, the largest producer of heavy clay machinery in the United States, needed to remodel some of their existing steel machine parts. The function of the machinery depends on the tight fit between the individual parts. In order for J.C. Steele to update and remodel their existing machinery, they would need to obtain scan data of 52 individual parts, which range anywhere between 30 to 300 pounds. 3DScanCo has proved to us that they have a

Revolver Manufacturer, Needed to Reproduce a Legacy Part Gun.

Situation Heritage Manufacturing, Inc., a revolver manufacturer, needed to reproduce a legacy part gun. Because Heritage had no existing CAD data to aid in design assistance, they would need to find a way to extract the dimensions of the housing and loading gate of the gun. The precise fit of the parts is critical to the function and safety of the gun. I’m very happy that our first project together went so smoothly and I look forward to working more

Gilbarco Seeking to Optimize Fluid Flow

Situation Gilbarco, a leading global supplier of fuel dispensing equipment, needed to optimize fluid flow through a complicated cast part. Gilbarco wanted to use computational fluid dynamic (CFD) analysis in order to quickly optimize the shape for fluid flow but no CAD data of the cast part existed. I’m very pleased with the work, and the great communication and service, and plan to use 3DScanco for any work of this type in the future.” Solution Gilbarco contracted 3DScanCo – a

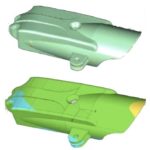

Laptop Lid Deflection

Situation While structurally strong and economically viable, most plastic parts today suffer from warpage of their otherwise rigid structure over long distances or under differing amounts of pressure. Deflection in laptop lids is a direct effect of the torsion contained in the hinges that keep the lid open. FAI Materials Testing Laboratory, a materials testing and failure analysis company, needed to quantify the amount of deflection in a laptop lid at various states of openness as part of their Finite

Hand Scan

Situation Denton ATD Inc, a leading provider of Anthromorphic Test Devices (ATDs), needed to update the shape and features of many of their existing ATDs. Because the parts were designed and manufactured many years ago, most lacked any CAD data. In order for Denton to update their manufacturing and design process, they would need CAD data of all the unique parts that comprise each ATD. We look forward to working with 3DScanCo for any type of 3D scanning work. They

CertainTeed Tile Cutter Project

Situation CertainTeed, a complete building products manufacture, needed to reverse engineer existing roofing tile cutters. The cutters are currently in use by CertainTeed, however no CAD model of the physical parts existed. In order to reproduce the cutters, certain needed to obtain CAD files and 2D Drawings of their parts. difficult without 3d scanning because the roofing tile cutters had a complex cross section and varying edge angles. The main reasons I will try and use 3DScanCo in the future

AGCO Agricultural Equipment Receives Some Fine Tuning

SITUATION AGCO, one of the world’s largest distributors of agricultural equipment, needed to recreate to key components of an engine coupler. The two large gears had combined cast and machined surfaces. At the time AGCO contacted 3DScanCo no CAD model of the coupler parts existed. The two parts to the coupler actually nest together and when in use the gear teeth mesh with each other. You guys are spoiling me – I really can’t explain enough how nice it is,

Bringing Back a Classic Street Rod: The Southern 408

Situation Based on and inspired by a ’54 Chevy, the Southern 408 looks and feels like an American classic. To help bring this classic street rod to market, Southern Motor Company partnered with Panoz Automotive. Because the ’54 Chevy is a legacy product, there was no CAD data available to use for design assistance. John Leverett, Director of Engineering at Panoz, knew that generating such data would require partners with expertise in the fields of 3D scanning and reverse engineering.

Engineered Plastic Products Inc

Situation Engineers often need to design parts that fit inside objects that lack CAD data. The measurements of these legacy parts are typically obtained via calipers or a Coordinate Measuring Machine (CMM). However, these methods often suffer from human error or cannot sufficiently measure the complex surfaces. Engineered Plastic Products, Inc. needed accurate models of a pair of OEM motorcycle chain covers in order to design new pieces to fit within the physical part. For EPP to ensure that the

Elan Motorsports Discovers Solution to DP02 Racer Dilemma

Situation Elan Motorsports uses a standard fiberglass lay-up process to create the shell (outer body mold) of their VanDiemen DP02 Sports Racer. Based off the model design of an existing racer body, Elan needed to know the shell’s dimensions in order to correctly place the engine and chassis. The DP02 also required optimization of packing density and weight ratios in order to maximize the performance of the car. Due to the complex and free form surfaces of the shell, as

Computational Methods

Situation Only recently has modern 3D scanning technologies been able to catch up with the demand for accurate scanning of large physical objects. Digital models of massive aircraft such as the Airbus A319 can be tested via computational fluid dynamics (CFD) if the model is accurate enough to the actual physical shape. 3D scanning technology is the most effective way to ensure this accuracy. Computational Methods, an aerodynamic analysis company, needed surface data of the Airbus A319 to model and