How Lasers Can Reduce the Cost of Quality- Precise scanning and measurement via simplified processes can help reduce costs and time-to-market. See IEN magazines full story…

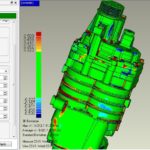

CT Analysis of Metal 3D Printed Parts

The printing of 3D metal parts is incredibly difficult. For example the slightest impurity in powered metal can be scanned and used, hit with a laser and popped creating a void inside that material that the next layer can easily cover up. If that void becomes denser and/or is in areas of high stress, the part can break and not support the intended weight. This is not yet a consistent or repeatable process yet and the only way to eliminate errors is with computer topography. More importantly, CT is able to do this without destroying the part being printed.

CyberOptics hits hypergrowth with faster 3-D scanning products

CyberOptics Corp. shares have tripled in value this year, performing better for investors than any other Minnesota-based company, and one of the reasons is a new device that makes very fast, very accurate 3-D scans of physical objects.

As Featured in SME: New Uses of Noncontact Metrology in Aerospace

Article first appeared on SME’s Advanced Manufacturing The question of how users can compare accuracy of one device to the next remains challenging Aircraft manufacturers are finding noncontact metrology ever more useful. Its inherent high throughput and decreasing cost is complementing the industry’s ramp-up to meet the world’s appetite for more airplanes. However, throughput needs to be balanced with accuracy in finding the right applications as noncontact embraces a variety of devices. “Noncontact metrology is either laser or optical based,”

Merit Medical Gains R&D Efficiencies with 3D Scanning

Merit Medical sought to gain increased efficiencies in the R&D phase of product development. The Laser Design DeskTom CT scanner expedited time-to-market, improved return on investment and improved operational efficiencies.

Proving ROI for 3D Scanning Technology in Industrial QA Applications

In this interview, Martin Schuster of Laser Design, Inc. talks about how replacing traditional QA systems with 3D scanning can streamline processes and reduce time-to-market.

Lobster Scanning with the Artec Space Spider

A research team on the East Coast needed high resolution information and texture detail of a lobster – a live lobster! In order to provide the critical detail needed the Laser Design 3D engineer used the Artec Space Spider.

3D Terrestrial Scan of Shattuck St. Mary’s

Shattuck St. Mary’s boarding school was in need of revamping their outdated construction documents into CAD format and turned to Laser Design for 3D terrestrial scanning.

Revolutionary DMLS Surgical Tool Repairs Ligaments, Restores Confidence

There are over 900 ligaments in the human body, each serving to support and connect hundreds of bones. The anterior cruciate ligament (ACL) is one of the most important ligaments connecting the tibia to the femur. An orthopedic surgeon set out to improve the success rate of ACL reconstruction by modifying the standard surgical technique using a 3D scanned & printed metal surgical tool.

Digital Recreation from the Scene of the Accident

3D scanning can be used successfully to settle legal disputes when physical evidence is key. The ultra accurate data provides definitive answers about how and why an accident happened to determine root cause and which party, if any, can be held liable for part failure.

Increasing Bottom-Line Profitability with 3D Scanning

Manufacturers strive for first-to-market position in introducing innovative products to the public – speed and quality give a competitive advantage . Reducing time to market with 3D scanning creates the biggest opportunity to increase bottom-line profitability.

3D Scan of Electric Car Opening Doors to the CAD Automotive World

Laser Design 3D scanning engineers was to scan the entire electric car body, chassis, and components (rather than an assembly) to create a viable CAD model. Since the car didn’t exist as an assembly,

Donnelly Speeds First-Article Inspection Turnaround

An injection molding company decided to expand its QA function with 3D scanning in direct response to customer demands for speedy precise inspection services for their increasingly more complex free-form and part surface profiles.

Old Radial Engines Made New: 3D Scanning Recreates Complex Fin Geometry

A DC-6 engine from WWII had very involved geometry including hundreds of proximate narrow cooling fins and internal features, the heavy-duty extant cylinder heads were too warped and damaged to function so they decided to reverse engineer new parts using 3D scanning.

3D Scanning Provides High-Quality Data of Custom Electric Guitar

A luthier made an ornate one-of-a-kind electric guitar body in the early 1980s and wanted to document his classic creation and create an updated version based on his 20-plus years of experience in the guitar making field – in order to do this he needed an exact 3D CAD model of the instrument only 3D scanning could provide.

Corvette Engine Cruises With High-Performance Part From 3D Scanning

A custom hand-crafted a molded intake tube was built for a Corvette to increase the high speed performance. To fabricate the tube a digital model was needed and 3D scanning was the only solution able to handle the challenge.

3D Scanning Brings Aspiring Car Designer Clay to Life

A 15 years old aspiring car designer sculpts his elaborate car design in clay but is looking for a more durable model of his cars, painted and detailed. He turns to 3D scanning for the 3D CAD data he needs to have his design fabricated.

Hot-Rod Restoration “Revved Up” with a 3D Scanner

RavenWorks’ employees, hot-rod enthusiasts every one, saw a need in the market for replacement parts for vintage vehicles. To faithfully reproduce select in-demand “extinct” parts, they came to Laser Design for a duel-purpose high-accuracy 3D scanner.

Duplicating a Distinctive Glass Bottle Mold with 3D Laser Scanning

3D laser scanning enabled this customer to preserve a true representation of one of their distinctive older bottle designs to document a part of their proud history!

What is the ROI of 3D Scanning?

A moldmaker wanted to re-qualify used molds to see if they needed refurbishing, and if so, where to make the corrections find out how the ROI of 3D Scanning was determined.

Designing Aftermarket Part from Casting with 3D Scanning

The customer was designing an improved aftermarket supercharger with a very complex shape from the external casting of an old OEM stock supercharger, for which there was no CAD model and looked to 3D scanning for a solution.

Municipal Cooling System Replaced with Minimal Downtime through 3D Scanning Services

An engineering firm was installing new cooling equipment in a municipal ice rink’s mechanical room. The challenge was to design the equipment install without tearing out the old equipment first and to install elements and piping around the current equipment configuration to limit downtime of the facility. They turned to 3D scanning services to map the entire room in 3D.

From Bottleneck to Project Accelerator with a 3D Scanner

A 3D scanner provides new inspection options and a faster alternative to CMM for this engineering and mold manufacturing company. As featured in MoldMaking Technology magazine!

Customer Uses 3D Reverse Engineering Services for Product Development and Huge Savings

The capabilities of Laser Design spans the gamut from high-accuracy reverse engineering services to 3D CAD model creation to product design and development to testing and analysis. This project for an optics company involved all of those phases – full engineering services to bring about a successful product launch.

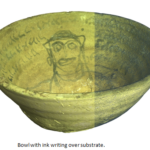

Digitally Archiving Museum of the Bible’s Collection

SITUATION Collectors of artifacts and other archeological finds know that the stewardship and preservation of their finds are just as important as finding them at all. While the science of restoration is always improving, the chemical processes that cause corrosion and deterioration of physical parts is unavoidable and oftentimes accelerated once an artifact is unearthed. The Museum of the Bible, a nonprofit museum in Washington, D.C., acquired their first biblical artifact in 2009, and since then has grown to a