The Nuisance of Optics In the world of 3D scanning, one can pick many different attributes to bifurcate the selection of 3D scanners. For example: a scanner can either be required to scan shiny objects, or it is not. When it comes to 3D scanning outdoors, the answer becomes murkier. Modern 3D technologies utilizes nearly the full electromagnetic spectrum, from X-Rays to radio waves, but everyday industrial 3D scanners mostly utilize optical technologies. Optical 3D scanners utilize visible light such

Artec Quick Set-Up Guide

Step 1 – Set up an Artec Account Artec 3D scanners require Artec Studio software to process data, and this software requires an Artec user account be created. Creating a new account is fast and easy. Please visit http://my.artec3d.com and register for a new account. You will then receive a registration email to confirm your account creation. Please notify your Laser Design representative when you have created your account! You may want to consider using an email address and password

Belly Tanker 3D Scanning Case Study Update

Some of you may remember the case study from June of 2021 where we featured Bob DeGezelle, a retired construction superintendent, and his pursuit of creating a belly tank racer that would compete to break land speed records at the Bonneville Salt Flats. We’ve heard from Bob and have some updates to share. Laser Design Case Study: https://www.laserdesign.com/high-precision-3d-scanning-using-artec-leo-for-custom-race-car-design Roll Cage Update After receiving the 3D CAD model deliverable from Laser Design, Bob engaged with a design and engineering team

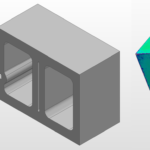

Reverse Engineering Deliverables from 3D Scan Data

3D scanning is a process that captures complex part and object surfaces and can produce measurements much faster and more accurately than with manual methods (i.e. calipers, gauges, etc…). Once the raw 3D scan data is captured of a physical part, what happens next? The most common step after raw 3D scan data is captured is to create a reverse engineered CAD (computer-aided design) model. CAD models are digital 2D and/or 3D representations of a part, or of an assembly

Get Your Game on With Artec Micro

Introduction For centuries, board games have provided education, training in military tactics and strategy, and simple entertainment for countless individuals worldwide. In general, these games have involved face to face interactions among the participants and some sort of physical equipment such as a playing board, dice, and small game pieces. With the development of technology, the focus on gaming is shifting to the domains of Virtual Reality (VR), Augmented Reality (AR) development. Now, gamers can interact with one another and

Archiving Movie History: Small Soldiers Movie Prop

Parting is Such Sweet Sorrow Stan Winston was a movie magician whose talent and creations are no doubt ingrained in the mind of most moviegoers around the world. With a movie history featuring the iconic looks from Aliens, Iron Man, Jurassic Park, and The Terminator, it’s no wonder original Stan Winston props attract a wide following both for sentimental and the obvious reason! Many years ago, Blake Beatnik le Saint acquired an original Stan Winston prop from the 1998 movie

Photorealistic Texture

INTRO If you’ve seen the Artec Space Spider in action, you’ll know that small objects such as baseballs can be scanned with incredible detail, with a high resolution able to capture small bumps and details in the stitching. This shape detail has been a mainstay of the Artec Space Spider since the original Artec Spider released in 2013. Over the years, the color capture has improved as a result of software improvements such as Glare Reduction added in Artec Studio

Going the Extra Mile

Introduction Surely, most of us have heard a customer service horror story or two. Like the one about someone getting put on hold for forty-five minutes only to have their call dropped before getting the chance to speak to the service technician about their malfunctioning computer, or of some poor soul standing in queue for over an hour at the airport just to find out that they’ve been standing in the wrong line and the correct line stretches down the

Top 3 Reasons Our Customers Choose Laser Design’s 3D Scanning Solutions

Laser Design has been passionate about 3D scanning for over 30 years. Being an industry leader with a long history of success comes from dedication and consistency. Throughout our history, we have successfully completed over 30,000 projects and we appreciate the ability to provide solutions to some of the most difficult 3D measurement challenges. We value our relationship with our customers, and it is our #1 priority to identify and provide the right solution for each of their needs. Through

A picture is worth $10,000

Everyone has heard the saying, “a picture is worth 1000 words”, but do you know how much a 3D scan is worth? Technological advances have provided many new and useful tools for measuring, re-creating, and, in other ways, characterizing manufactured parts that were never available or even imaginable to our predecessors. One such advancement has been in the development of accurate 3D scanning technology. New capabilities continue to emerge in the areas of data collection, evaluation, and analysis. Nowadays, many

Methods of Automation Within Artec Studio

Artec 3D users have long known of the power that handheld 3D scanners provide: fast, accurate, flexible, and easy to use, all contained within a handheld device an operator uses with controlled motion, rhythm, and mechanics. A dance of art and science. Data processing on the other hand still requires essentially a human being, sitting (or standing) at a computer, clicking away on a mouse and tapping away at a keyboard. Compared to scanning, data processing feels kind of boring.

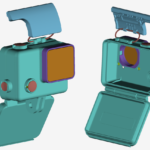

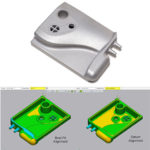

CT Scanning and Reverse Engineer Multi-Part Assemblies

Creating an assembly model of a GoPro® Camera Case Over the past 30+ years, Laser Design has received many requests from our customers to support their 3D scanning and reverse engineering needs focused on measuring and creating 3D CAD of an assembly made up of two or more parts. Initial conversations focus on what the customer will use the deliverable for and progress into details that help us understand how we can successfully measure the parts to acquire the geometry

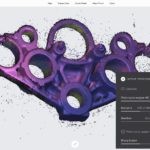

Artec 3D Launches Artec Studio 16 with New Tools and Enhancements Including Artec Cloud

Artec 3D recently announced the availability of Artec Studio 16 (AS16), the newest iteration of its award-winning 3D scanning software, and Artec Cloud, a collaborative platform that allows users to access, view, comment on, and process 3D scan data online. The integration of AS16 and Artec Cloud streamlines 3D project management. Users can upload and share 3D data with peers, leave comments, send photos, and have full conversations. With Artec Cloud, users can also process 3D scans in their browser

Back To School – 5 Blogs to Support Your Evaluation of 3D Scanners for Classroom and Laboratory Use

Students are flooding back to school, and whether in-person or online, the pursuit and love of knowledge is at the center of it all. For those returning to a department outfitted with a 3D scanner, this may be the most exciting time of the year. 3D scanning is here to stay as part of the way people live their lives, run their businesses, and recreate, so learning as much as possible while you can is important to gain a competitive

Essential Tools to Master in Artec Studio for Highest Quality Data – Basics and HD Mode

5 Essential Tools to Master in Artec Studio Software For all the glory that the Artec 3D portable scanners receive, we can’t forget that Artec Studio 3D scanning software is the “secret sauce” that makes the whole process work so well. Built to take your 3D scanning projects from scan to polygon-model-export, Artec Studio contains a simple and intuitive core workflow, as well as myriad branches of processing tools and elements that help you handle all of your unique and

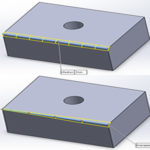

Reverse Engineering Modeling Methods – As-Built or Design-Intent

Laser Design, a CyberOptics Corporation brand, has been a leading provider of 3D scanning and reverse engineering services for over 30 years. Whether your company is in the automotive, aerospace, defense, electronics, medical or any other manufacturing industry, the most important question to answer during a reverse engineering project discussion is if an “as-built” or “design-intent” CAD model is needed. By providing Laser Design with your project end goal and/or your downstream application requirements, our highly skilled and experienced technical

Benefits and Things to Consider When 3D Scanning Flowers and Plants

High-Definition Botanical 3D Scanning Depending on where you live, in mid-May, spring might finally be here, or perhaps the summer heat is right around the corner. The birds are chirping, the flowers are blooming, and wedding bells are in the air. It also turns out that 3D scanning flowers is a budding new field thanks to advances in 3D scanning processing software from Artec 3D. Artec Studio Version 14, 15, and 15.1 software released a bunch of new texture/color processing

Laser Design, a CyberOptics Corporation Brand, is ISO 9001:2015 Certified

Laser Design, a CyberOptics Corporation brand, is ISO 9001:2015 certified. CyberOptics Corporation maintains a Quality Management System in compliance with the ISO 9001:2015 standard and it adopts a process, data driven and continuous improvement approach using risk-based thinking to ensure our products and services provide the highest customer satisfaction. Our Quality Management System provides us with the methods to effectively determine customer requirements, create solutions to meet those requirements, and deliver products and services conforming to those requirements. Additional details

Increase 3D CT Scan Data Inspection, Visualization and Analysis Capabilities with myVGL Viewer Software

For many years, the standard deliverable for inspection results from a 3D scanner has been an exported report in PDF format that includes both tabular and visual deviation information. From a 30,000-foot view of the deviation of an as-built part, as compared to a nominal CAD file, to GD&T dimensional analysis results for 10’s to 100’s of dimensions, these reports were a great way to illustrate part characteristics in a more real world, 3-dimensional view. However, the info provided in

4 Easy Steps to NURBS Surface Modeling in Geomagic Design X

What is NURBS Surface Modeling? This computerized 3D modeling method consists of applying digital contours and surface patches directly on 3D scan data to represent the geometry of the 3D scanned object mathematically. When searching for information on NURBS modeling, you will find that the acronym stands for Non-Uniform Rational Basis Splines (B-Splines). What you may not learn easily is that NURBS surface creation techniques are best applied when modeling complex and freeform shapes, as the final model represents the

Artec Micro to Artec Space Spider Comparison

A Closer Look Tag Team Champions In a previous blog post, we covered the Artec Micro 3D scanner and its key strengths relative to the Artec Space Spider, namely, the high-resolution and automated 3D scanning powers of the Micro being a step beyond its handheld counterpart. While amazing for small objects like jewelry, the Artec Micro’s main limitation is its working volume, being unlikely to scan anything larger than a few inches in diameter. Because of this limitation, the Space

Artec Micro Overview

A Powerful Scanner in a Small Package 3D scanners have come a long way in their 30+ year history. With parallels to the development of the first computers, the first 3D scanners were comparatively giant machines compared to the small handheld scanners that exist nowadays, such as the Artec Space Spider and Leo 3D scanners. Unlike their PC counterparts however, large machine-like 3D scanners still have a bona fide use in common 3D scanning applications. For example, the highest accuracy

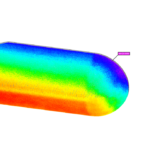

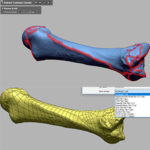

Dimensionally compare your Physical Part to CAD using CyberOptics XLP Laser Scanner and Geomagic Control X Software

Measuring part and assembly geometry throughout the manufacturing process is critical to verifying as-built features meet specified tolerances and that completed parts perform as-designed. Whether the need is for first article inspection, non-destructive analysis or tool wear verification, the required processes can be tough for engineers due to a variety of challenges including speed, repeatability, ease of use and accuracy. The “old school” method to check a manufactured part is to perform hand measurements with a variety of tools including

How to Fix Movement on a Child 3D Scan

Movement in Body Scanning If you’ve ever attended an Artec demonstration with Laser Design, or read our previous blog on correcting for movement, you’ve probably heard the phrase: “Fix it in post”. In the 3D scanning world, this means small mistakes can be made during scanning, but they will be fixed during post-processing. For example, a heavy-duty Artec carrying case with a hinged handle will contain two rigid subcomponents: the case, and the handle, and when flipping the case upside-down,

Artec Eva and Artec Leo 3D Scanners Receive High Definition (HD) Upgrade

As the progress of technology marches on, consumers will rightfully wonder more and more whether their purchase of some product today will become obsolete by tomorrow. Although cell phones and PC operating systems have conditioned us to assume the availability of software updates after purchase, very few of us expect massive overhauls, much less anything more than marginal new features. Artec 3D shocked the world by announcing a collection of new features summed up as: Artec HD Mode! Available for