Situation Scaling hand made sculptures is extremely difficult, time consuming, and sometimes impossible. Urbana needed to create a master pattern of their hand made sculpture for plaster casting. Since the plaster would shrink after production a scale factor up from the originally had to be used, but to do this without scanning would mean creating several very similar parts for the various production methods. 3DScanCo has remained in contact with ARINC and worked hard to give us a deliverable in

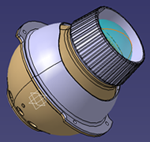

Aircraft Lightbulb Assembly

Situation The CAD Workshop, a Dassault Systemes training company, needed to obtain CAD data of an aircraft lightbulb unit, which consists of an assembly of 9 separate parts. Before creating a CATIA assembly model, 3DScanCo’s – a division of Laser Design Inc. – challenge was in correctly orienting and aligning the 9 sets of scan data to create an accurate representation of the entire lightbulb unit. I have been well pleased with outcomes from 3DScanCo. Very professional and extremely knowledgeable

Team Technologies Requires Scanning Services

Situation Blister packs and other thermoformed parts often present problems to design engineers. Frequently there are numerous complex shapes, blends, and radii. Team Technologies, a leading manufacturer in Dental, Medical, Cosmetic, and Industrial Products, had two thermoformed blister packs. Team Technologies needed to manufacture these parts but had no way of creating the molds. I feel you have the right combination of creative engineering balanced with a well grounded foundation of what it takes to commercialize a new technology like

Ancient Chinese Dagger Is Priceless

Situation Collectors of ancient artifacts know that while rare and sometimes extremely valuable, the preservation and maintenance of relics of the past is of the upmost importance. While restoration of such antiquities can extend their life, the chemical reactions taking place within their ancient materials mean that decay and deterioration is unavoidable. Priceless Past, a distributor and service provider of ancient artifacts, had acquired a Bronze dagger dating back to the 5th century BCE from the Qiang minority in ancient

Panoramic Inc Packaging Project

Situation Panoramic Inc., a designer and manufacturer of custom thermoformed plastic packaging products, needed to reverse engineer existing paper packaging to create new plastic packaging. The existing paper packaging held consumer products, no CAD of the consumer products or the existing packaging was available for Panoramic to design new plastic packaging from. Panaromic needed to quickly create a CAD model so they could cut new thermoform tooling. We look forward to working with 3DScanCo for any type of 3D scanning

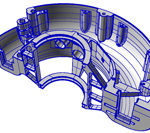

Desktop-Sized Donut Scanning Project

Situation Microprocessor Designs, a product design and development company, needed to obtain CAD data of a desktop-sized ‘donut’ consisting of four sections. The complex sections contain numerous bolt-holes and features which are critical to the function and fit of the part. In order to obtain CAD data, Microprocessor Designs would need to reverse engineer their existing physical part to match the design intent. I’m very pleased with the work, and the great communication and service, and plan to use 3DScanco

Steel Machine Parts Receive Remodel

Situation J.C. Steele & Sons, the largest producer of heavy clay machinery in the United States, needed to remodel some of their existing steel machine parts. The function of the machinery depends on the tight fit between the individual parts. In order for J.C. Steele to update and remodel their existing machinery, they would need to obtain scan data of 52 individual parts, which range anywhere between 30 to 300 pounds. 3DScanCo has proved to us that they have a

Revolver Manufacturer, Needed to Reproduce a Legacy Part Gun.

Situation Heritage Manufacturing, Inc., a revolver manufacturer, needed to reproduce a legacy part gun. Because Heritage had no existing CAD data to aid in design assistance, they would need to find a way to extract the dimensions of the housing and loading gate of the gun. The precise fit of the parts is critical to the function and safety of the gun. I’m very happy that our first project together went so smoothly and I look forward to working more

Gilbarco Seeking to Optimize Fluid Flow

Situation Gilbarco, a leading global supplier of fuel dispensing equipment, needed to optimize fluid flow through a complicated cast part. Gilbarco wanted to use computational fluid dynamic (CFD) analysis in order to quickly optimize the shape for fluid flow but no CAD data of the cast part existed. I’m very pleased with the work, and the great communication and service, and plan to use 3DScanco for any work of this type in the future.” Solution Gilbarco contracted 3DScanCo – a

Laptop Lid Deflection

Situation While structurally strong and economically viable, most plastic parts today suffer from warpage of their otherwise rigid structure over long distances or under differing amounts of pressure. Deflection in laptop lids is a direct effect of the torsion contained in the hinges that keep the lid open. FAI Materials Testing Laboratory, a materials testing and failure analysis company, needed to quantify the amount of deflection in a laptop lid at various states of openness as part of their Finite

Hand Scan

Situation Denton ATD Inc, a leading provider of Anthromorphic Test Devices (ATDs), needed to update the shape and features of many of their existing ATDs. Because the parts were designed and manufactured many years ago, most lacked any CAD data. In order for Denton to update their manufacturing and design process, they would need CAD data of all the unique parts that comprise each ATD. We look forward to working with 3DScanCo for any type of 3D scanning work. They

CertainTeed Tile Cutter Project

Situation CertainTeed, a complete building products manufacture, needed to reverse engineer existing roofing tile cutters. The cutters are currently in use by CertainTeed, however no CAD model of the physical parts existed. In order to reproduce the cutters, certain needed to obtain CAD files and 2D Drawings of their parts. difficult without 3d scanning because the roofing tile cutters had a complex cross section and varying edge angles. The main reasons I will try and use 3DScanCo in the future

AGCO Agricultural Equipment Receives Some Fine Tuning

SITUATION AGCO, one of the world’s largest distributors of agricultural equipment, needed to recreate to key components of an engine coupler. The two large gears had combined cast and machined surfaces. At the time AGCO contacted 3DScanCo no CAD model of the coupler parts existed. The two parts to the coupler actually nest together and when in use the gear teeth mesh with each other. You guys are spoiling me – I really can’t explain enough how nice it is,

Bringing Back a Classic Street Rod: The Southern 408

Situation Based on and inspired by a ’54 Chevy, the Southern 408 looks and feels like an American classic. To help bring this classic street rod to market, Southern Motor Company partnered with Panoz Automotive. Because the ’54 Chevy is a legacy product, there was no CAD data available to use for design assistance. John Leverett, Director of Engineering at Panoz, knew that generating such data would require partners with expertise in the fields of 3D scanning and reverse engineering.

Engineered Plastic Products Inc

Situation Engineers often need to design parts that fit inside objects that lack CAD data. The measurements of these legacy parts are typically obtained via calipers or a Coordinate Measuring Machine (CMM). However, these methods often suffer from human error or cannot sufficiently measure the complex surfaces. Engineered Plastic Products, Inc. needed accurate models of a pair of OEM motorcycle chain covers in order to design new pieces to fit within the physical part. For EPP to ensure that the

Elan Motorsports Discovers Solution to DP02 Racer Dilemma

Situation Elan Motorsports uses a standard fiberglass lay-up process to create the shell (outer body mold) of their VanDiemen DP02 Sports Racer. Based off the model design of an existing racer body, Elan needed to know the shell’s dimensions in order to correctly place the engine and chassis. The DP02 also required optimization of packing density and weight ratios in order to maximize the performance of the car. Due to the complex and free form surfaces of the shell, as

Computational Methods

Situation Only recently has modern 3D scanning technologies been able to catch up with the demand for accurate scanning of large physical objects. Digital models of massive aircraft such as the Airbus A319 can be tested via computational fluid dynamics (CFD) if the model is accurate enough to the actual physical shape. 3D scanning technology is the most effective way to ensure this accuracy. Computational Methods, an aerodynamic analysis company, needed surface data of the Airbus A319 to model and

3D Scan of Three million-year-old Horse Skull

The National Park Service’s Hagerman Fossil Beds National Monument in Idaho contains the largest concentration of Hagerman Horse (Equus simplicidens) fossils in North America. It is nationally and internationally significant for its world-class paleontological resources including the world’s richest fossil deposits, in quality, quantity, and diversity, from the late Pliocene epoch. Many of its fossils represent the last vestiges of species that existed before the last Ice Age, the Pleistocene, and the earliest modern flora and fauna. The NPS paleontologists

Improving Comfort and Safety for Elite Racecar Drivers through Custom Seats and Headrests

Situation BSCI Energy Impact Systems is a leader in the development and research of foam safety components and has pioneered innovations that have set the industry standard in professional racing. BSCI’s successes are driven by their understanding of the importance of properly designed and functioning padding inside the car – padding that helps protect drivers from the tremendous forces applied during a crash. Top drivers from around the world come to BSCI for custom-fit seats that perfectly match the shape

NASA’s Aeronautical Research Lab Flying High With Critically Modified Fairings

Situation In 1994, NASA obtained a specially modified Boeing 757-200 to be used for aeronautical research. Named the ARIES, or Airborne Research Integrated Experiments System, the aircraft has gone through numerous customizations and modifications to earn its “flying laboratory” nickname. Over time, NASA realized that in order to maintain the ARIES as its premier research aircraft, they would need to modify the fairings. In order to do this, NASA would need much higher quality CAD data of the jet in

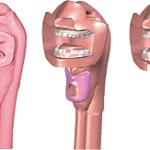

High-Quality Medical Training on Airway Replica Maintained Using Breakthrough Internal 3D Scanning Process

Situation Medical training programs are the cornerstone of successful medical practice. Medical Education Technologies Inc. (METI), a developer of medical training products, lost its only supplier of the PediaSIM® airway, leaving them with physical models, but no CAD data and no way to manufacture them. Not wanting to completely redevelop the product, METI sought to reverse engineer CAD data from the limited number of physical parts they had left. METI made several attempts to reverse engineer the design. However, the

Labor-Intensive Prototyping Cycle for Marine OEM Products Streamlined with 3D Laser Scanning

Situation Engineered Metals and Composites, Inc. (EM&C) is the premier OEM manufacturer of aluminum towers and small products for the marine industry. From T-tops, hard tops and towers, to rod holders, leaning posts, rails and poling platforms, they provide the highest quality enhancements and accessories for fishing and pleasure boats. In order to create these products, EM&C’s craftsmen design and manually shape the towers to fit the boats, which can be a laborious and time-intensive process. For EM&C to maintain

Troops Protected through Precise Life-Saving Up-Armoring of Trucks

Situation The vast amount of supplies being sent into Iraq has been key to the U.S. Military’s efforts in the region. Convoys of trucks loaded with supplies have been entering Iraq from Kuwait for the past several years; however, the lightly armored trucks offer very little protection for the drivers against projectiles and explosives. DRS Radian was contracted to develop armor kits for several models of trucks in order to ensure the safety of the drivers. However, CAD data was

Perfect CAD Data Enabled CAE Precision Testing on MC-130E Radar System

Situation Since its introduction in the 1960s, the MC-130E Talon I has been modified on a nearly continuous basis to incorporate more and more modern technology into its legacy design. One such addition is of a state-of-the-art radar system which would be housed inside a radome that was hand-crafted from fiberglass in the 1950s. Computer Aided Engineering (CAE) would have to be performed by MI Technologies to test a variety of functions of the radar system inside the radome. In

SEMA’s Best New Interior Product: Deep and Precisely Fitted Jeep Floormats

Situation Omix-Ada is the premier manufacturer of Jeep replacement, restoration and accessory products, including the Rugged Ridge accessory line of floormats. Currently, Jeep floormats are either “carpet,” thermoformed rubber that fits the car, or “deep” all-weather flat floormats that are not formed to fit. Omix-Ada wanted to combine the advantages of both types of mats to create OEM-quality mats that are both formed to the vehicle and deep. However, they needed help in both capturing the exact cab floor geometry

- « Previous Page

- 1

- …

- 5

- 6

- 7

- 8

- Next Page »