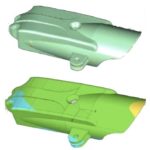

Many industries are now benefitting from the increased speed of 3D laser scanning to significantly reduce the time required for product development,functional analysis, and inspection of their products. Schneider Electric, a global manufacturer of high-precision plastic molded parts, has significantly sped up and improved the quality inspection process in several of their international manufacturing facilities while saving several million dollars a year with the portable Laser Design SURVEYOR FA Series scanning system; overall the company has experienced near 40% reduction

One Laser Scanner Delivers Multiple Applications

Schneider Electric, a huge multinational corporation, specializes in world-class power and control products, through its excellent brands, Merlin Gerin, Square D, and Telemecanique, that fulfill customers’ requirements in the residential, building, industry, energy, and infrastructure markets. When the specialist in process improvement at Schneider Electric first used Laser Design’s Surveyor DS laser scanning system, he expected to acquire clean, accurate scan data, and his expectations were more than met. What he didn’t expect was being able to use the same

3D Scan of Three million-year-old Horse Skull

The National Park Service’s Hagerman Fossil Beds National Monument in Idaho contains the largest concentration of Hagerman Horse (Equus simplicidens) fossils in North America. It is nationally and internationally significant for its world-class paleontological resources including the world’s richest fossil deposits, in quality, quantity, and diversity, from the late Pliocene epoch. Many of its fossils represent the last vestiges of species that existed before the last Ice Age, the Pleistocene, and the earliest modern flora and fauna. The NPS paleontologists

As-Built vs. Design Intent: A Reverse Engineering Dilemma

Laser Design Inspection Services has been a leading provider of dimensional inspection, 3D laser scanning, terrestrial scanning, and CT scanning services forover 25 years. The company’s metrologists and engineers are experienced in the automotive, defense, electronics, and many other manufacturing industries. One issue that has been common in reverse engineering scanning projects for all industries over the years is making sure that customers know exactly what type of CAD file deliverable they want from Laser Design based on what they will

Long Range Scanning: As Featured in Professional Surveyor

In the early 1990s GPS was a new and amazing, even if a seldom-used technology. Although the military had been using GPS for over a decade, civilian surveyors were skeptical of its necessity when non-electronic hand tools had sufficed since the beginning of their profession.However, it became apparent that the benefits of GPS were such an enormous boon that its use slowly gained acceptance over the years until today it is ubiquitous for all surveying projects. Using GPS to provide

3D Laser Scanning in the Metal Fabricating / Sheet Metal Industry

3D laser scanning offers tremendous time savings and cost benefits for the metal fabricating and sheet metal forming industry. Most importantly, it provides the ability to reverse engineer and inspect complex parts, assemblies and tooling to a higher level of accuracy and in a shorter period of time than with other methods. Instead of collecting points one by one like a coordinate measuring machine (CMM) does, the laser scanner captures tens of thousands of points per second by sensing thereflection

Case Study Portfolio

3M Design Corrected Mid Project The need for safety & protection of people working in facilities is increasing, which prompted 3M’s Occupational Health and Environmental Safety division to develop a new face shield for welders. Well into the design process they were unhappy with the aesthetics of the design and felt the concept to CAD and to rapid prototypes was not working– a major correction to the design was needed in the middle of project execution. A clay model was

3D Laser Scanning Makes an “Impression” on the Dental Profession

Dentistry’s roots date back to prehistoric times when the practice consisted mainly of tooth drilling and extractions. The science of modern dentistry can be traced back to the 17th century when prosthetics and fillings were added to the original list of treatments. Since its humble beginnings, the field of dentistry has advanced and grown to include preventative, surgical, restorative, and cosmetic areas as well. Today dentists, orthodontists, and oral surgeons need advanced technologies to support their advanced care of the

Accuracy Study on WS-Series System

Executive Summary It is often difficult to describe the accuracy of a 3D Laser Scanning system, because, to date, there is no unified standard that governs it. The typical scanning system from Laser Design is a CMM base with a laser line sensor attached in place of a touch probe. While determining the accuracy of the CMM base is simply a matter of running an ANSI B89 Ball Bar test using a touch probe, no such standard test exists for

CMM Laser Probe Interface

MOTION TRANSPORT RETROFITTING Interfacing an LDI Laser Probe to a Motion System Other Relevant Documents MCSDK.chm which is a motion control driver development guide. CMM or CNC Retrofit Flow, which is a flow chart describing the process of retrofitting a motion transport system with a laser probe. CMM Retrofit Form, which is a questionnaire to be filled out prior to configuring the retrofit kit. General The laser probes collect dimensional data in their own reference frame, and in their own

Anthropology- Primate Teeth

Worn teeth are a bane to paleobiologists interested in the diets of human ancestors and other fossil primates. Although worn teeth dominate fossil assemblages, their shapes are usually not used to reconstruct the diets of extinct species. The problem is that traditional studies of primate dental functional anatomy have focused on unworn morphology. This has limited most functional analyses to only a few well-represented fossil species. This paper introduces a method to characterize and compare worn occlusal morphology in primates

Laser Scanning Improves Reverse Engineering and Inspection Tasks

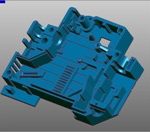

A wide range of moldmakers are adopting the emerging technology of 3D Laser Scanning in order to improve the accuracy and substantially reduce the time and cost of reverse engineering and inspection tasks. 3D Laser Scanners capture up to 50,000 coordinate points every second, drastically improving reverse engineering and inspection speed and accuracy. Using a laser scanner instead of a touch probe based digitizer or touch probe scanning device mounted on a machining center or CMM (Coordinate Measuring Machine) for

Capture 15,000 Points Per Second By Equipping CMM with Laser Probe

Laser scanners capture thousands of points every second, drastically improving reverse engineering and inspection speed and accuracy. As a result, many companies are either replacing their Coordinate Measurement Machines (CMMs) with laser scanners or purchasing laser scanners instead of CMMs as they expand their operations. But other companies are looking at the large investments they have made in their existing CMMs and asking if they can be preserved or enhanced by equipping them with a laser probe. The answer is

New Advances in 3D Laser Scanning Technologies From Laser Design

At Laser Design, laser scanning technology has been adapted for a variety of high-tech solutions to common challenges faced by manufacturing companies around the world. Laser Design, Inc (LDI) manufactures laser triangulation sensors and complete scanning machines used for measuring parts. LDI also creates the software that controls the motion of both the lasers and the machines, and collects and edits the scan data. Founded in 1987, the company has transitioned from an almost exclusively R & D operation to

Distribution Partnership for Industrial CT 3D Scanner Announced

Laser Design, Inc. (LDI), a global provider of 3D scanning systems and services, announced a partnership with Rx Solutions of France for North American distribution of the Rx Solutions DeskTom CT 3D Scanner. The DeskTom system is designed to address the rapidly-growing market for 3D Dimensional Metrology and Non-Destructive Testing (NDT) solutions. Rx Solutions teamed up with LDI because of LDI’s extensive experience marketing and supporting high-accuracy 3D scanning solutions. Computed tomography (CT) scanners have the ability to scan both

Laser Design Releases 3D Anti-Glare Scan Spray

Laser Design, Inc. (LDI), a global provider of dimensional inspection and 3D scanning equipment and services, now offers a new anti-reflection coating for achieving optimal accuracy during laser scanning. Reflectivity is detrimental to 3D data acquisition, so it is often necessary to apply an anti-glare coating to objects before 3D scanning. Helling 3D Scan Spray, from Helling GmbH and distributed in North America by Laser Design, is a great option for this due to its thin and uniform adherence to

Rus Emerick Joins Us as Director of Applications Engineering

Laser Design, Inc. (LDI), a global provider of dimensional inspection and 3D scanning equipment and services, welcomed Rus Emerick in March of this year as its Director of Applications Engineering. Emerick joins LDI after a distinguished career at Schneider Electric. During his 21 years at Schneider, he served as their Process Improvement Specialist and 3D Imaging Global Process Owner. He specialized in 3D laser scanning, computed tomography (CT) analysis, reverse engineering, global management, and training. Key to his success was

Innovation at Versatile Mold Scanning EDM Electrodes

The quality team at Versatile Mold, led by Albert Whitaker, Director of Quality and Trevor Martin, Quality Technician, were challenged to figure out how to distinguish Versatile Mold from their competitors. They felt there was no better way than to improve their quality while shortening the design and qualification cycle. Determining that the earlier in a project errors might be detected led them to a very innovative process. They would verify the correctness of an injection molding tool BEFORE any

Quick Case Study- Outboard Motor

John purchased a miniature motorized “toy” outboard motor from Ebay and wanted to reproduce using a more substantial motor/gearing set up for R/C use. The outboard is 6 inches tall and the two halves can separate to easily remove the internal components. He contacted an RP company but quickly realized he would need a 3D Solidworks model first. Laser Design Services scanned the outboard motor for a RC device and gave him CAD models and ABS prototype part in about 8

Verifying Assemblies Using CT Scans and Geomagic

Rus Emerick, Global Process Owner for 3D Imaging at Schneider Electric, spends a lot of time thinking about tolerances. Starting with tolerances of individual parts, his brain moves swiftly on to the effect of chains of tolerances that, once you get to 4, 5 or more parts in an assembly, could cumulatively affect the reliability of the products being made at any of their manufacturing and design sites in 22 countries around the world. But how can the consistency of

Long-Range Scanning Busts Crunch-Time Large-Scale Project Deadline

Company: This southeastern U.S. company provides general contracting, construction management, and design/build services for larger commercial, industrial, and institutional projects. Challenge: With a deadline of just three weeks looming, new material-conveying systems had to be installed into existing structures at nine far-flung sites. The modifications would expand capabilities to new structures while avoiding interferences with old ones. The scale of the entire project was huge due to the large sizes of the onsite locations, the distance between locations, and the

New Tricks for Old Dogs: Veterinary Surgical Hip Replacement

Company: The well established East Coast company designs, develops, and manufactures state-of-the-art veterinary orthopedic implants for small animals. It holds patents on several designs addressing clinical needs in the canine hip, knee, and elbow. Standards for articulating surfaces of implants which meet or exceed those specified for human implants are maintained in all its products. The company is represented in over 95% of the US Veterinary Teaching Universities, selected international universities, and specialty clinics all over the world. Challenge: With

Laser Design Engineering Services Customer, Sbyke® Wins Two Prestigious Awards

Laser Design is proud to announce that one of their engineering services customers, Sbyke USA, LLC, has won awards for its outstanding patented rear-steer kick scooter from both Popular Science and Parenting magazines. Receiving top honors in Popular Science’s “Wheel Wars” competition and Parenting’s “Best in Play,” the sbyke® was also an instant hit at the American International Toy Fair in New York, 2011. Sbyke co-founders Steve and Bart Wilson wanted to use the most advanced technologies to design, test,

Drive Like the Pros: Racing Teams and Aficionados Sharpen Skills and Improve Performance with Advanced Full-Motion Simulator

Company: Founded in early 2007 on the West Coast, this high-tech engineering firm has revolutionized the design and manufacture of advanced full-motion personal racing simulation equipment. Its highly specialized products are used not only in professional racing team training and testing environments, but also in private homes, motoring clubs, racing schools, and specialized retail settings. Each simulator is individually assembled, tested, installed, and fully supported. Challenge: The company designed a mounting system for a specific racing seat in a new

Loud and Clear: 3D Scanning Perfectly Reproduces Miniaturized Printed Circuit Boards for Microphone Products

Company: The southern U.S. company manufactures voice products for mic’ing people on stage, TV, and movie production. Challenge: Complex electronics are getting smaller all the time. In the case of microphones, smaller versions for performers mean less interference with their ability to move and act as the role demands. The company wanted to further miniaturize their microphone products, which required developing smaller printed circuit boards (PCB) and redesigning their housings. The housings had to be the smallest possible size to

- « Previous Page

- 1

- …

- 4

- 5

- 6

- 7

- 8

- Next Page »