Inspection & Metrology

Give our 3D Scan team a call! 952-252-3479

Laser Design’s experienced engineers use the latest digitizing and software technologies available for non-contact measurement to perform 3D scanning inspection for your company.

To deliver the best of both worlds, we combine both 3D scanning and touch-probe measurement to deliver ultra-precise dimensions on your project – in our lab or on-site anywhere in the world.

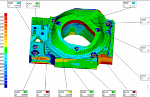

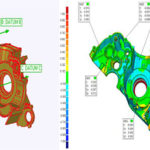

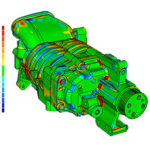

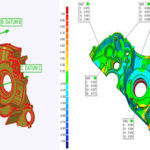

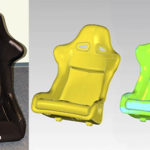

3D inspection or dimensional metrology, assesses the geometric characteristics of your parts and objects to assure compliance with design specifications. 3D inspection will verify the accuracy of your projects features that can affect reliability and functionality – this can be a critical step during product development or following production.

3D inspection or dimensional metrology, assesses the geometric characteristics of your parts and objects to assure compliance with design specifications. 3D inspection will verify the accuracy of your projects features that can affect reliability and functionality – this can be a critical step during product development or following production.

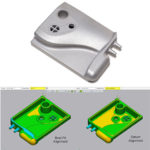

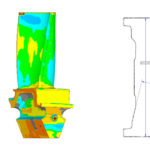

Through the measurement of a physical part, 3D scan data is compared directly with the nominal CAD model to verify that the finished part or tooling conforms to the original design intent. Alternately, two sets of point cloud scan data can be compared with each other during the manufacturing process to assure parts stay in spec.

Laser Design is committed to investing in secure resources that ensure that all of our ITAR data is stored in a manner that meets or exceeds the ITAR requirements. With Laser Design you know your ITAR project is not only compliant but being fulfilled by a company that is registered.

Laser Design is committed to investing in secure resources that ensure that all of our ITAR data is stored in a manner that meets or exceeds the ITAR requirements. With Laser Design you know your ITAR project is not only compliant but being fulfilled by a company that is registered.

Learn more about our ITAR Registration

Learn more about 3D Scanning

Get a Sample Scan File