3D Laser Scanning – Over 30 Years and 25,000 Successful Projects Completed!

What Is 3D Laser Scanning?

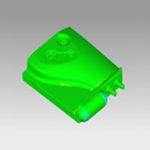

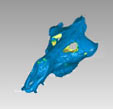

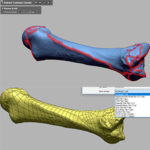

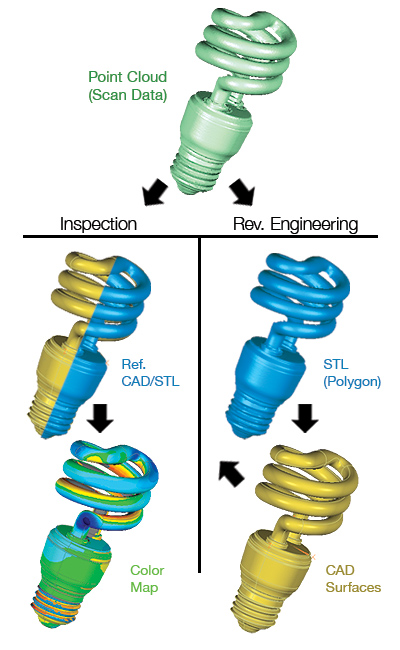

3D laser scanning, the process of converting physical objects into precise digital models, enables you to quickly and accurately capture your object’s shape and geometries. Raw 3D scan data consists of millions of XYZ data points, called “point clouds,” which can be manipulated and delivered in a number of native file formats. This process supplies you with a complete digital representation of your part to be used for reverse engineering, quality inspection, or analysis at any point of a typical manufacturing cycle.

3D laser scanning technology can provide you with:

Give our 3D Scan team a call! 952-252-3479

- Fast, ultra-accurate results, reducing your time to market and cutting labor and material needs—saving you both time and money! When compared to traditional hand measuring methods, 3D scanning services are exponentially more efficient, quick, accurate, and detailed.

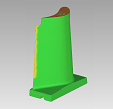

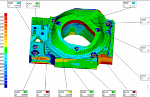

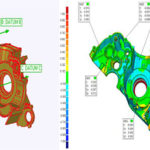

- Complete measurement data of the entire surface of your object, verifying that the as-built part matches your CAD model. Discovering any defects or deviations from the design-intent model will allow you to readjust sooner and keep your project or production on track.

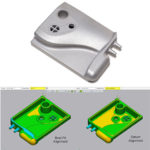

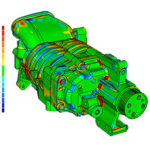

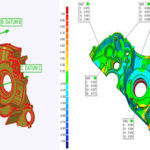

- True CAD models for FEA testing of actual geometry to correct problems before parts go into production. This application can allow you to conserve valuable resources and manpower.

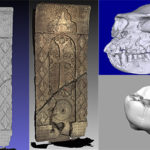

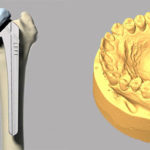

- CAD models to validate tooling, even when no current models exist. Because 3D scanning is non-contact and non-destructive, you’ll be able to safely and effectively capture data for unique, delicate, complex, or tiny parts and prototypes.

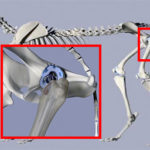

- Profile data of the whole part so assemblies can be digitally put together, revealing inaccuracies and interferences.

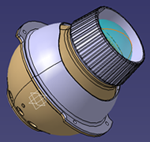

- Customized digital models of your parts in whatever format you need them in, with whatever level of detail, color, and texture you require. You won’t need to struggle with an unfamiliar file format—our scanning services team can deliver your data in a variety of file formats. We can convert raw 3D scan data into a SOLIDWORKS CAD model, for example.

3D Laser Scanning Deliverables and Applications

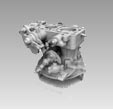

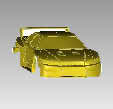

With 30 years of successful 3D scanning projects under our belts, Laser Design can scan everything from tiny components to vehicles and even entire buildings. We provide customers with unparalleled technology and expertise, both on-site and in our lab. Our 3D scanning services team is eager to work with you to identify the right solution for your project—and then put it into action.

We can deliver in many native formats:

We can deliver in many native formats:

- AutoCAD

- SolidWorks

- Pro/E

- CATIA

- UG

- IDEAS

- Autodesk Inventor

- Rhino

- Revit

- CAE/CAM

- And others

Whether comparing a physical part to its CAD model, digitizing a prototype with the intent of developing a new CAD model, or generating missing parts documentation, the 3D scanning process yields high-accuracy point cloud data that can be modeled and used for just about anything under the sun. The following are just a few of the many possible uses for 3D scan data:

- Tool path creation

- Polygonal / STL meshes

- Composite blends

- NURBS curves

- NURBS surfaces

- Tooling verification

- And many more

How 3D Scanning Services Can Streamline Your Project

You don’t have to be a 3D scanning expert or purchase your own equipment to benefit from this versatile technology—that’s where we come in. Partnering with Laser Design’s 3D scanning services bureau will make executing a successful project that much simpler.

- Whether you have a one-off project or require ongoing 3D scanning services, our team will be available wherever and whenever you need us.

- With our experienced 3D scanning technicians on your side, there’s no learning curve to worry about. We’ll scan and process your data, providing the exact output you need for your purposes.

- If you need tight turnaround on a budget, you’ve come to the right place. Our 3D scanning services are cost-competitive and significantly faster and more accurate than traditional hand measuring.