The Nuisance of Optics

In the world of 3D scanning, one can pick many different attributes to bifurcate the selection of 3D scanners. For example: a scanner can either be required to scan shiny objects, or it is not. When it comes to 3D scanning outdoors, the answer becomes murkier. Modern 3D technologies utilizes nearly the full electromagnetic spectrum, from X-Rays to radio waves, but everyday industrial 3D scanners mostly utilize optical technologies. Optical 3D scanners utilize visible light such as red lasers or projected white light in order to function, and it has several key advantages such as being lightweight, cheap, and safe, especially compared to CT X-Ray 3D scanning. Most importantly, optical 3D scanners are the most common, utilized by most manufacturers such as Artec 3D. Optical 3D scanners suffer from their own set of challenges which impact how well they can be used outdoors, and there are non-technological barriers to consider as well.

The Nuance of Optics

Optical 3D scanners utilize a form of “call and response” technology to obtain 3D data. In a nutshell, photons of light are emitted from the scanner, where they interact with an object, and sensors collect the reflected light. Software crunches the data and turns it into useable 3D models. This ensures that data is to-scale and differentiates true 3D scanners from photo-modeling alternatives. The key challenge to this method is our cosmic caretaker: Sol.

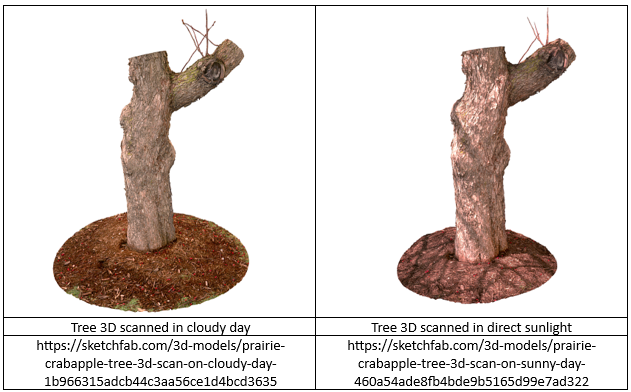

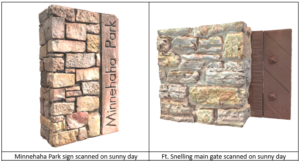

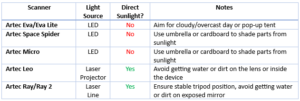

The sun is a very powerful light source, and a 3D scanner utilizing projector bulbs or LEDs does not bring enough photonic firepower to the front. This is due to the properties of projected light that it rapidly degrades in intensity over distance. It would be like trying to listen to a violin soloist amongst a full crowd at a baseball stadium. This is true for projected light technologies that utilize light bulbs or LEDs such as the Artec Eva. Scanning outdoors with the Artec Eva requires a solution to the sun: a cloudy day is usually the best solution, but a pop-up tent or method of blocking the light will work as scanning in indirect sunlight with LEDs will work. Lasers do not suffer this same fate because laser scanners emit a stream of photons in a mostly straight line, keeping the intensity high even over long distances. This allows laser scanners to puncture through the otherwise oppressively bright light source from the sun.

Police Officer 3D scanned on cloudy day

Types of Laser Scanners

Laser Scanners can be divided into 2 kinds: LIDAR, and Laser Projection. LIDAR is the method most commonly understood by the public: a laser line sweeps over an area and everything the laser line passes over is collected in 3D. Movies such as Aliens and Prometheus show laser scanners in this way. This technology is also what many self-driving cars utilize in order to map 3D space – it works in direct sunlight. The Artec Ray and Ray 2 long range laser scanners utilize this form of technology.

3D Scanning a glider with Artec Ray and Artec Leo

The alternate way of using lasers is via projection. Much like bulbs and LEDs can project a pattern on a wall, lasers have been utilized to do the same thing. Laser based pico-projectors are a relatively new innovation and many commercialized products already use them. Traditional projectors (like in a conference room) first utilized incandescent bulbs which would get very hot, and eventually the technology was miniaturized using low temperature LEDs instead. Laser projectors miniaturize the technology even further, allowing truly pocket-sized portable projection. The Artec Leo utilizes a laser projector instead of LED bulbs, and this allows the Leo to be utilized even in direct sunlight.

Coming Into Focus

Once the lighting conditions have been understood and the right technology is chosen, the final confounding variables relate to weather, particle, and environmental conditions. 3D scanners are warm inside, requiring cooling vents that can allow for solid and liquid ingress. Rain, mist, snow, etc. on an otherwise cloudy day risks allowing water inside the scanner, potentially causing long term damage. Particle movement such as smoke, sand, or wind can blow dust and debris into exposed ventilation and could possibly contact the lenses and mirrors which would require delicate cleaning. Finally, environmental conditions such as vibrations due to heavy machinery or wind blowing connected components can cause challenges scanning if the object moves during scanning.

With that in mind, below is a table summary of the various Artec 3D scanners, light source, and outdoor scanning competence:

About Laser Design

Laser Design, a CyberOptics Corporation Brand, has been a leading supplier of 3D scanning systems and services since 1987. Laser Design helps customers successfully solve their most complex 3D inspection, analysis, and reverse engineering challenges quickly, giving them a competitive advantage.

Whether the 3D solution needed is a new 3D scanner or a service project performed in our lab or at your site – Laser Design’s expert metrologists and experienced engineers have you covered – on your schedule, within your budget and with ultra accuracy & results our customers have come to expect.