Given the level of sophistication that technology has achieved in the 21st century, you would think that the architecture, engineering, and construction (AEC) industry would have already adopted an advanced solution across the board for projects involving inaccessible areas, such as wind turbines and telecommunication structures—but this isn’t the case. Traditional measuring methods require technicians to scale structures hundreds of feet tall, which creates challenges for both safety and efficiency. Fortunately, a solution does exist, and it’s growing in popularity.

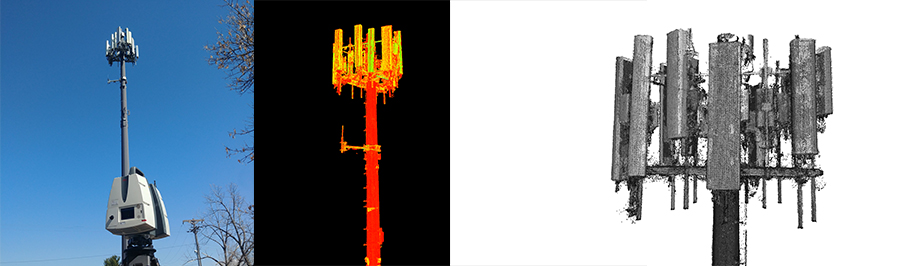

3D terrestrial laser scanning can be used to capture an enormous amount of data in traditionally inaccessible places. This is particularly useful for projects involving very tall objects like high voltage transmission towers, cell phone towers, and wind turbines. Overall, the efficiency and accuracy provided by terrestrial laser scanning result in significant project savings in terms of time and money with this safer method.

How 3D Laser Scanning Can Streamline Your Workflow

Terrestrial laser scanners like the Artec Ray use powerful laser technology to quickly generate digital representations of objects and structures. Laser light makes it possible to scan over long distances in outdoor conditions, meaning that it’s possible to capture scan data anywhere, at any time. And, thanks to this technology, project timelines are no longer dictated by the size of the structure that needs to be measured.

The result? Millions of XYZ points, or “point cloud” data, that can be modeled and manipulated for use across teams. You might think of terrestrial 3D scanning as the most direct route to acquiring the data you need to get the job done.

What Can 3D Scan Data Be Used For?

The data generated during the 3D laser scanning process can be delivered in a number of file formats and used for multiple purposes, including the following:

- Structural analysis

- CAD modeling

- BIM integration

- Reverse engineering

- Evaluating maintenance needs

- Inspecting potential implementation sites

- As-built documentation

- Elevation drawings

When it comes to very large structures like telecommunication towers and wind turbines, terrestrial scanning proves useful for both installation and maintenance projects. Whether you’re evaluating the integrity of a potential installation site for a cellphone tower or working to evaluate damage to an inoperable wind turbine, the point cloud data generated by a 3D scan will allow you to accomplish your task quickly, efficiently, and safely.

4 Benefits of Terrestrial Laser Scanning for Inaccessible Areas

Let’s take a closer look at the value that terrestrial 3D scanning can add to a project.

1. Accuracy

Traditional measurement methods may risk the safety of team members, particularly on projects involving massive structures like wind turbines. But on top of that, those traditional methods aren’t foolproof. Terrestrial 3D scanning captures very complete and accurate measurement data that far surpasses what is provided by traditional measurement methods, whether you’re scanning complex mechanical rooms or exterior structures. This increased accuracy eliminates revisits for the measurement team. Once data has been captured, it can be used to create highly accurate CAD models for documentation and future design efforts.

2. Efficiency

Another advantage of terrestrial 3D scanning is that elevated areas can be measured very quickly and completely. The technology can be used to capture millions of measurement points of steel and composite structures, turbine vane alignment, mounting fixtures, positions of transmission equipment, antennas, and more. And, as we mentioned, the accuracy of 3D laser scanning reduces rework stemming from faulty documentation, saving hundreds of hours in planning time and misspent labor.

3. Safer Conditions

You simply can’t put a price on safety. Where traditional measuring methods have technicians climbing hundreds of feet to measure large structures, 3D scanning can be performed from the ground—and even a significant distance away from the structure in question. This adds an invaluable increase in safety and a decrease in liability to a project.

4. Lower Costs

Lastly, terrestrial 3D scanning eliminates field modification of new equipment by identifying interference potentials before installation, leading to faster project completion time and reduced expense. This can allow you to come in under budget and complete work before a deadline, potentially earning early completion bonuses. This added efficiency will allow you to win more projects with leaner processes, leading to a lower end cost for you and any customers you may have.

3D Laser Scanning Units and Services From Laser Design

Terrestrial laser scanning represents a significant opportunity to cut down on project costs and shorten completion time. We’re here to help you reap the many benefits of this powerful technology. Laser Design, a CyberOptics Corporation brand, has been providing high-quality 3D scanning services and 3D scanners to a variety of customers throughout the AEC industry for over 30 years.

Whether you’re installing a high-voltage transmission tower, engineering a new design in Revit, or analyzing structural performance with Finite Element Analysis, our talented team will work with you to identify the right 3D solution that will streamline your project. Contact us today to learn more about our 3D scanning services bureau or purchasing your own scanner.