3D printers use specific digital files to create three-dimensional physical parts and other objects. They are particularly useful for fabricating parts with complex or irregular geometry that might otherwise be difficult to construct, along with creating working samples of unique prototypes for testing, development, and manufacturing. Clearly, the applications for this technology are numerous—but before you can begin making use of 3D-printed parts and objects, you’ll need a digital version in a usable file format.

While there are a variety of methods for collecting the base dimensional measurements, 3D scanning is the quickest, most cost-effective, and overall most efficient method. Furthermore, the data can be used for reverse engineering applications that then lend themselves to the 3D printing process. Laser Design, a CyberOptics Corporation brand, offers both on-site and in-lab 3D scanning reverse engineering services to streamline your project, help with missing parts documentation, and more. Put the calipers aside, and let’s examine how this technology can be used for 3D printing applications.

What Is 3D Scanning, and How Does It Fit With 3D Printing?

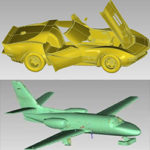

3D scanning employs laser, projected light or computed tomography (CT) technology to create an exact digital representation of a physical object. Each of these three forms of 3D scanning technology are non-contact and non-destructive, making it ideal for modeling everything from intricate, delicate parts to massive buildings.

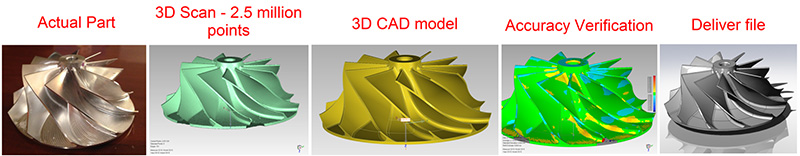

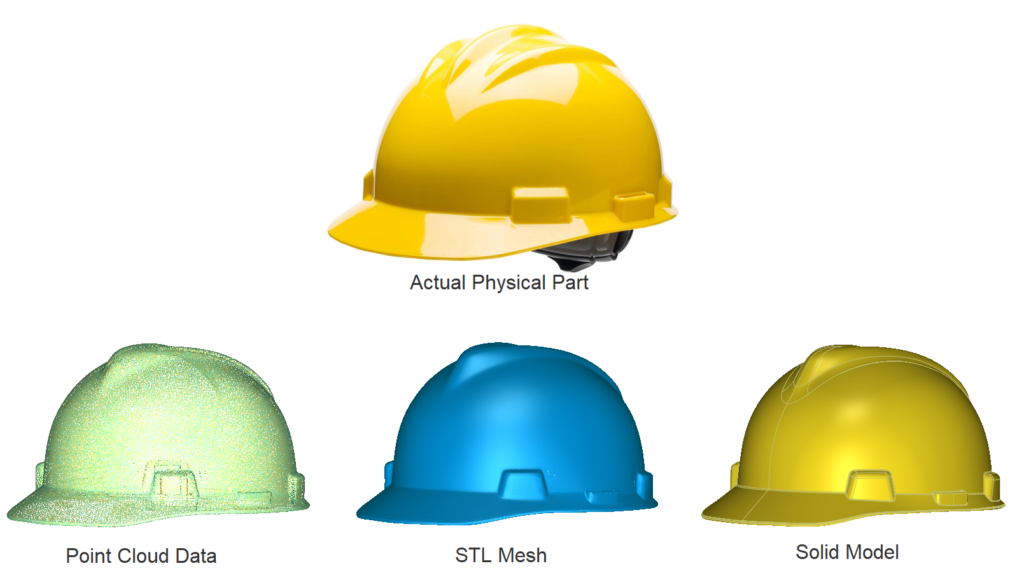

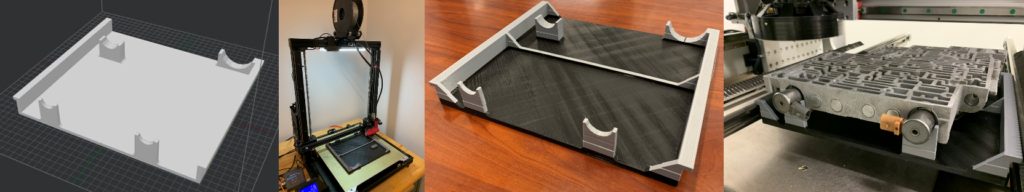

3D scan data is captured in the form of millions of XYZ data points, called a point cloud. These point clouds can be converted to a watertight mesh file, or they can be used directly to create a CAD model (which can also be converted to a different type of mesh file), and a number of other deliverables. When saved as specific file formats, the 3D printer software will recognize the 3D data, and you’ll be able to physically print a part or object based on your model.

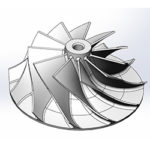

This versatility of point cloud data from 3D scanning is especially useful when it comes to reverse engineering. Millions of XYZ measurements can be used to create a CAD model of a physical object, no matter how complex or free-form its shape may be. Our team of skilled 3D scanning technicians can customize your CAD model to represent the part’s as-built shape or provide the geometry with its original, as-designed, features—it’s all up to you.

What File Formats Are Used for 3D Printing?

STL (short for “stereolithography”) is the most common file format understood by 3D printers, although there are dozens of others. This particular format encodes the surface geometry of a 3D object by fitting triangles together so that they fill the surface without overlapping (a process known as tessellation).

VRML (“vermal”) is another universally accepted file format for 3D printing. While STL files only support a single color, VRML files include multiple colors and can be used on desktop 3D printers equipped with multiple extruders or full-color binder jetting capabilities.

Are All 3D-Printed Files Created the Same Way?

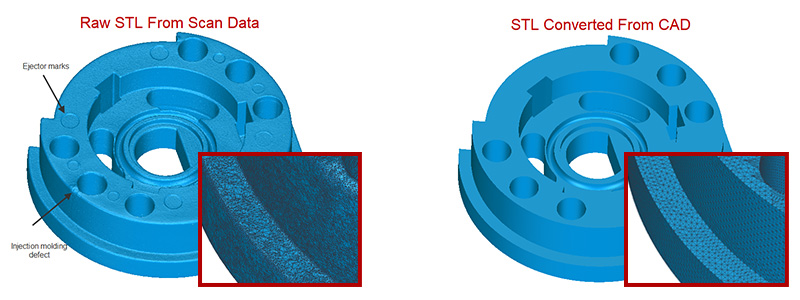

While STL is one of the most popular file formats for 3D printing, not all STL files are created in the same way. Raw STL files created from 3D scan data provide a high level of detail, capturing an exact reproduction of the scanned part. However, these files typically take up quite a bit of space, and they will include defects like warped areas and deformations—helpful for part inspection and analysis, but not so helpful for 3D printing a working model from an imperfect or organic prototype.

On the other hand, STL files converted from CAD data use mathematically-defined geometry, meaning that the surfaces of the model will be flat, features will be squared or perpendicular, and hole diameters will be perfectly round. These files are smaller in size, easier to work with and excel where prismatic shapes are needed. The cost to create a watertight STL from points vs. from a reverse engineered CAD model will depend on the size of the part, the curvature complexity, the amount of mesh editing needed and the number of features on the part.

What Can Be 3D Scanned?

When it comes down to it, just about any object can be scanned and modeled using a 3D scanner, whether for reverse engineering, inspection, or analysis purposes. That data can then be converted into an STL file format for 3D printing. The Laser Design team has scanned everything from a lifesaving stent to sports stadiums! That being said, we can break down the various categories of parts and objects that are typically scanned.

Tiny, Small, and Medium-Sized Parts and Objects

Small components can be quite challenging to measure and model manually. Fortunately, 3D scanning can be used in place of hand measuring to create an incredibly accurate and detailed representation of your part. Laser Design’s 3D scanning services bureau can deliver these files in many different native formats, including neutral formats like STP and IGS to native formats like SOLIDWORKS, Creo and others. 3D scan data of these smaller parts and objects can be used to create everything from STL and NURBS surfaces to fully parametric CAD models.

Human Bodies

Body scanning enables the safe capture of data and modeling of the entire human body, along with individual body parts. In terms of 3D printing, we’ve seen these digitized models used for such varied pursuits as creating customized figurines, unique orthopedics and prosthetics, wearable technologies and much more.

Large Parts and Vehicles

While 3D scanning is an excellent option for creating digital representations of small parts, the technology also shines when it comes to documenting large objects and vehicles. This technology can take some of the pressure off a project limited by internal capabilities and access to critical features. With non-contact 3D scanning technology, large castings, aircraft and other vehicles can be measured in ways not possible with manual methods.

Buildings and Scenes

Buildings are yet another example of digital modeling made easy with the help of 3D scanners. In just a few hours, our 3D scanning technicians can produce data that would take a full measuring team much longer to create by hand. The resulting data can be used to produce 3D CAD models, verify architecture, create updated as-built documentation, and more. Not only will it save you labor and reduce costs, but it will also leave you with a wealth of data that can be converted into everything from as-built documentation to fly-through presentations.

Available Outputs for Specific Part Type

We can deliver data in a number of file formats and model types—here are just a few examples.

| ● STL files, as mentioned, are one of the most universally recognized 3D mesh file formats for 3D printing. STLs can be created from raw point cloud data or converted from a CAD model. |  |

| ● NURBS modeling, also known as “direct modeling,” provides designers with a “what you see is what you get” model. The totally non-parametric toolset is an excellent choice for projects involving highly organic design, sculpting, concept design, generative design, and de-featuring for analysis. NURBS models provide a great balance for communicating organic shapes in a file format that is widely used (STP or IGS). |  |

| ● A parametric model is a history-based model that requires a designer to build features and surfaces by using sketches and editing features. This type of modeling allows for full modification as each entity can be adjusted and the overall 3D geometry can be rebuilt given proper constraints. |  |

What If I Want to Change the Design Before 3D Printing?

Whether you’re using laser scanning for reverse engineering a missing part or creating a digital model from an imperfect prototype, you’ll likely need to make some changes to your design before 3D printing. The good news is that raw data captured during the 3D scanning process is incredibly versatile and can be converted into a number of application specific file formats. For example, you might take your as-built model, with all its defects and imperfections, and change the design to create a design-intent 3D model.

Additional Uses of CAD

While you can easily go straight from 3D scanning to 3D printing your digital model, you may find a number of other uses for your CAD model created from 3D scanning and reverse engineering. The following are just a few examples of the many directions in which you can take your CAD model.

- Explore existing designs

- Reconstruct an outdated product

- Uncover part vulnerabilities and defects

- Bring less expensive and more efficient products to market

- Create a reliable reference model

- Apply new, creative ideas to existing ideas

- Perform high-level competitive analysis

- Quick and simple fixture designs

Streamline Your 3D Printing Project With 3D Scanning Reverse Engineering Services

This is just a brief overview of the immense potential and versatility that 3D scanning can bring to your reverse engineering and 3D printing projects. Whether you require a speedy surface model or a fully parametric file, our team has the experience and insight needed to set unique performance goals and deliver the solution that’s right for you. If you’re ready to get started or are interested in learning more about our 3D scanning services, don’t hesitate to reach out to Laser Design. We look forward to putting our 30 years of experience in reverse engineering and 3D scanning to work for you.