Nondestructive, 3D Scanning of Internal and External Geometries

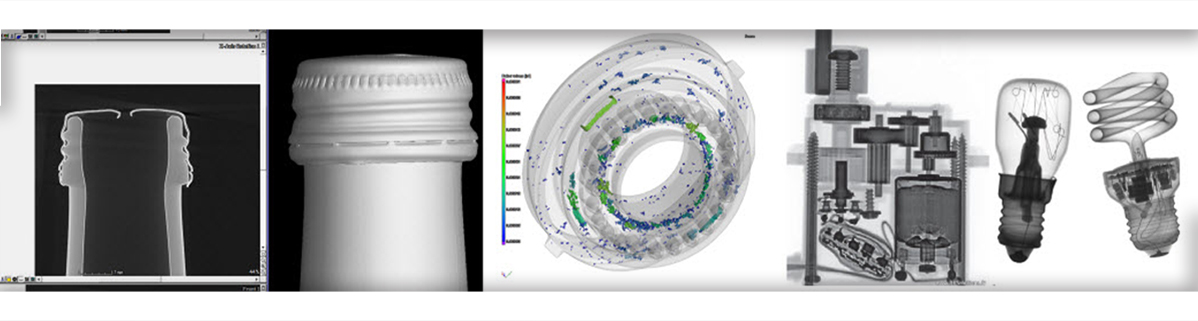

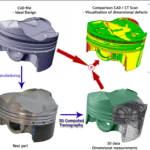

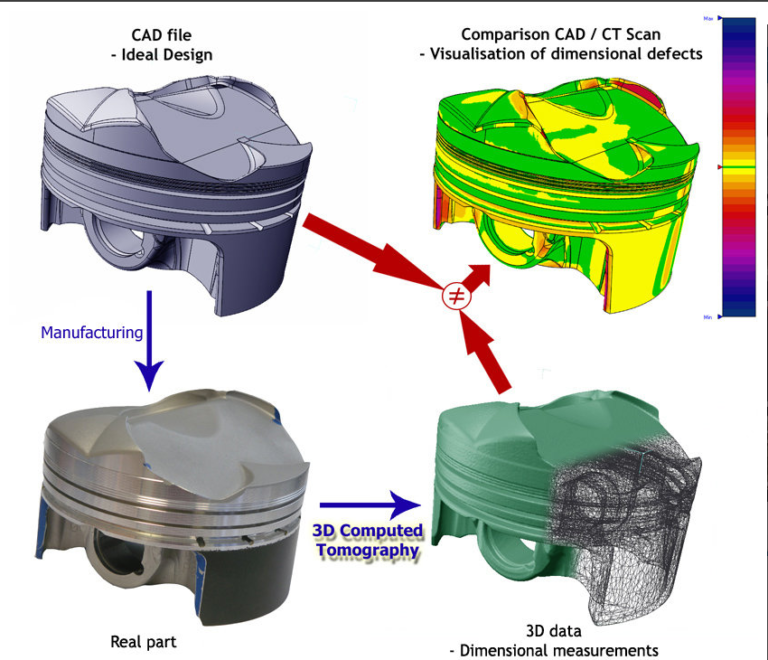

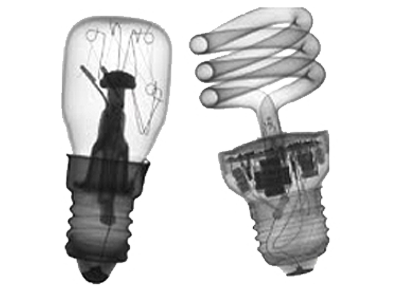

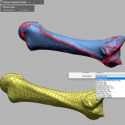

Metrology grade Computed Tomography (CT) inspection allows a complete 3D capture of complex internal geometry of parts without needing visual access – the process is nondestructive.

Resolution: to 4µ Accuracy to: +/- 5µ

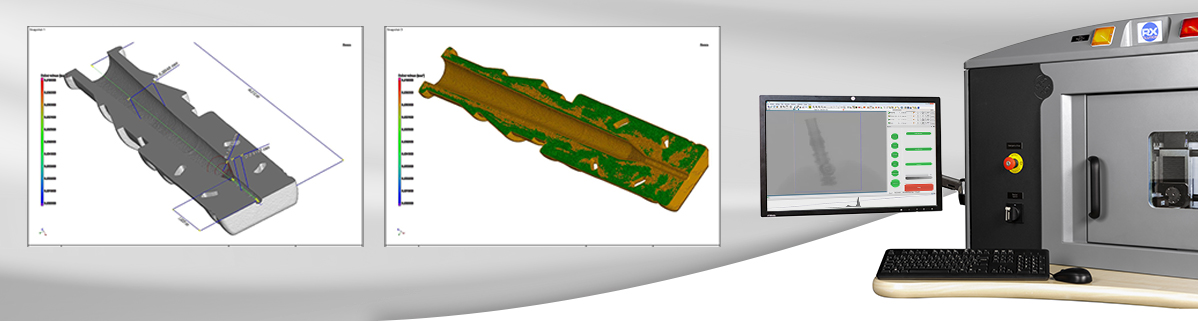

Our engineers utilize Volume Graphics and other software programs for your CT inspection needs. Volume Graphics provides analysis and visualization software for industrial CT scan data and is the premier digital workflow management software for CT analysis.

Laser Design offers both CT Scanning services & systems:

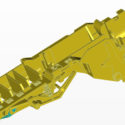

- CT Scanning Services– have your complex parts 3D scanned and inspected by Laser Design engineers for complex internal and external geometry with Industrial X-ray 3D scanning.

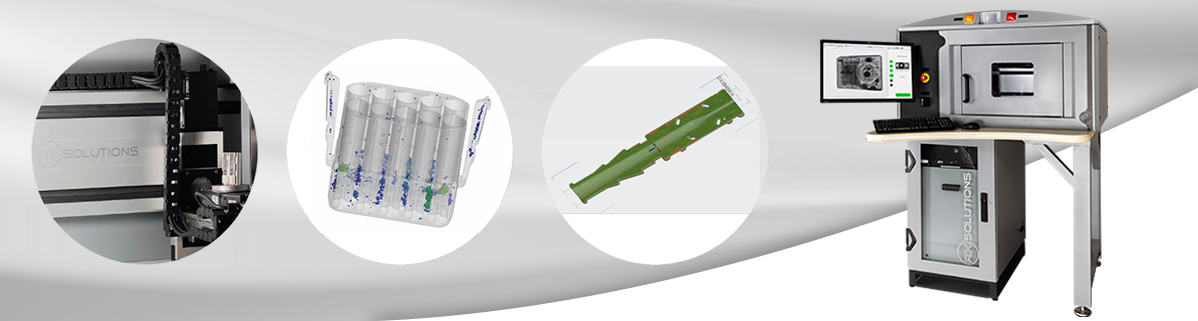

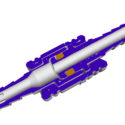

- The DeskTom CT Scanner is an x-ray inspection machine with computed tomography (CT) allowing collection of complex internal and external geometry. Parts fabricated from materials such as thermoset and thermoplastics, ceramics or composite materials, as well as magnesium, aluminum and steel can be measured and efficiently evaluated. Internal structures and assemblies as well as fiber analysis and porosity can easily be visualized, analyzed and documented.

This CT scanner is not only compact but one of the most affordable CT Scanners on the market!

- The EasyTom CT Scanners provide ultra 3D accuracy and resolution for large volume inspection.The EasyTom 3D CT micro and nano tomography features high resolution digital radioscopy, versatility for a wide variety of applications, 6 motion axis and large volume inspection.

Ask a 3D Expert - Microsite

Benefits of CT Scanning:

- Non-destructive inspection of your parts; line of sight or visual access to any surface is not required for CT scanning, yet 100% of the surface data is captured Your object, material or system will not be compromised or impaired, so its future usefulness is kept intact

- CT Scanning can provide accuracy on small parts of +/-0.010mm andon larger parts of +/-0.025mm (depending on size of part)

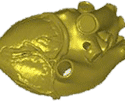

- Parts with small, complex, and fine geometry from the medical and electronics industries benefit especially from this technology, since they are very difficult to measure using even the most advanced, laser-based scanning or CMM technologies

- Customizable two- and three-dimensional inspections of small- to medium-sized objects generate 3D XYZ scan data in standard file format outputs for inspection and reverse engineering applications.

- CT scanning helps you capture all surfaces, both external and internal, of complex and free-form parts without damage to the object.

CT Scanning Photo Gallery

The Laser Design 3D Scanning Team has been busy! Besides a busy lab (that is also ITAR certified) we’ve also been to the World Trade Center, the new U.S. Bank Stadium, Space Needle, Miami Airport, ships in Korea, the Mirage volcano and more! We have the experience and know-how to tackle your next project whether it’s a small hearing aid or an entire ship! Check out our gallery of CT scanned photos.

CTScanning Videos

CT Sample Files for Download

CTScanning Case Studies

-

4 Easy Steps to NURBS Surface Modeling in Geomagic Design X

4 Easy Steps to NURBS Surface Modeling in Geomagic Design X

-

Case Study – Using EasyTom CT Scanner and Volume Graphics Analysis Software for Defect Detection

Case Study – Using EasyTom CT Scanner and Volume Graphics Analysis Software for Defect Detection

-

Case Study – CT Scanning Baseballs

Case Study – CT Scanning Baseballs

-

Merit Medical Gains R&D Efficiencies with 3D Scanning

Merit Medical Gains R&D Efficiencies with 3D Scanning

-

Just what the Doctor Ordered: Innovative Medical Applications of Non-Contact 3D Scanning

Just what the Doctor Ordered: Innovative Medical Applications of Non-Contact 3D Scanning

-

Verifying Assemblies Using CT Scans and Geomagic

Verifying Assemblies Using CT Scans and Geomagic

-

Laser Design adds EasyTom Industrial CT Scanner to Services Division

Laser Design adds EasyTom Industrial CT Scanner to Services Division

-

Application Story – Medical Device 3D CT Scanning

Application Story – Medical Device 3D CT Scanning