3D laser scanning enabled this customer to preserve a true representation of one of their distinctive older bottle designs to document a part of their proud history!

enabled this customer to preserve a true representation of one of their distinctive older bottle designs to document a part of their proud history!

The Customer:

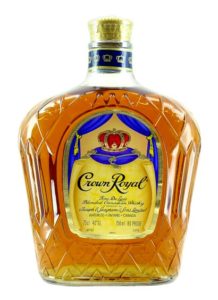

The customer was an established maker of fine spirits, with a distinctive (and very complex) glass bottle design.

The Challenge:

The customer’s glass bottle mold was damaged and needed to be replaced. Due to its old age, no digital data existed for the complex and detailed bottle so they were unable to make repairs to the original mold in CAD. They needed a precise CAD model so that they could digitally “repair” the damaged areas. The perfectly repaired CAD model would then be used to machine a new mold, making a true duplicate of the original design.

The Solution:

Two casts were taken by the customer from the damaged mold, a male and a female. Laser Design metrologists laser scanned the male cast on the Laser Design Surveyor WS-Series system using the SLP-500 laser probe. Scanning time was 40 minutes. Over 1.5 million points were collected in the point cloud data. Conventional measuring would have been extremely difficult due to the detail in the glass bottle and would have taken much longer, yielding a less complete data set.

The Results:

Once the scanning was complete, the massive amount of point cloud data was cleaned up to produce an STL polygon mesh file for the customer. This data editing and file creation took approximately 4 hours.

The STL mesh was edited to develop CAD surfaces of the undamaged, original bottle shape and made into a non-parametric solid model.