CAD-Based Inspection

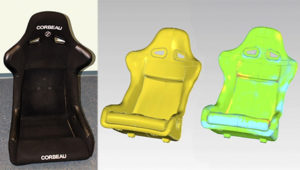

CAD-based inspection is the absolute best way to inspect a part’s fidelity to its design. 3D inspection services from Laser Design can quickly compare high-quality scan data to CAD using specialized software from metrology mainstays such as Geomagic and Volume Graphics. This part-to-CAD inspection is one of the fastest inspection methods available to QA/QC professionals.

CAD-based inspection is the absolute best way to inspect a part’s fidelity to its design. 3D inspection services from Laser Design can quickly compare high-quality scan data to CAD using specialized software from metrology mainstays such as Geomagic and Volume Graphics. This part-to-CAD inspection is one of the fastest inspection methods available to QA/QC professionals.

In the case of legacy parts that do not have existing CAD, Laser Design’s reverse engineering services can create CAD using an existing part as a template. Utilizing over thirty years of design and manufacturing experience, determinations can be made regarding the likely design-intent of an object or assembly. The resulting CAD can then be used for part-to-CAD inspection of future iterations of the part, product, or assembly.