Situation

Situation

Engineered Metals and Composites, Inc. (EM&C) is the premier OEM manufacturer of aluminum towers and small products for the marine industry. From T-tops, hard tops and towers, to rod holders, leaning posts, rails and poling platforms, they provide the highest quality enhancements and accessories for fishing and pleasure boats.

In order to create these products, EM&C’s craftsmen design and manually shape the towers to fit the boats, which can be a laborious and time-intensive process. For EM&C to maintain their competitive prices, they would need to upgrade their manufacturing process to take advantage of computer modeling technologies that would increase quality and decrease production time.

3DScanCo’s engineering talents and will to go beyond the call of duty on short notice was critical in our being awarded a multi-million dollar contract.”

Solution

Solution

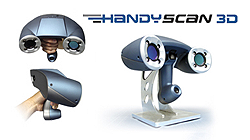

EM&C contacted 3DScanCo — a division of Laser Design Inc — about possible solutions to the manufacturing challenges they faced. 3DScanCo consulted with EM&C to incorporate 3D scanning into their existing manufacturing process – a valuable tool that would accurately capture data before modeling and thus reduce their prototyping cycle.

3DScanCo’s engineers traveled to EM&C’s manufacturing workshop to perform a demonstration of the Handyscan 3D, a handheld 3D scanning system, and Geomagic Shape reverse engineering software. This solution would be able to precisely document new and existing designs for later use, as well as ensure the tightest fit possible of EM&C’s products to their customers’ boats. After taking advantage of 3DScanCo’s extensive two day on-site training program, EM&C was able to easily redefine their manufacturing process through the use of 3D scanning.

Results

Results

“I was impressed by how knowledgeable and helpful 3DScanCo’s engineers are. They quickly got up to speed and consulted us every step of the way during our project, and provided training and support for all of our technical questions.

3DScanCo’s helpful and consultative nature throughout the entire process allowed them to come up with a solution to fit our exact needs – and it worked! We have seen increases in accuracy, manufacturing efficiency, and product quality, and would not hesitate to work with you again in the future.” – Angela Snelgrove, Draftsman, EM&C, Inc.