Client:

A local mechanical design contractor was faced with engineering a complete MEP overhaul at MSP International Airport. Existing documentation of the site was outdated, incomplete, inaccurate, and difficult to obtain. 3D laser scanning was utilized to help facilitate the process to complete the building information of what was already existing.

Project:

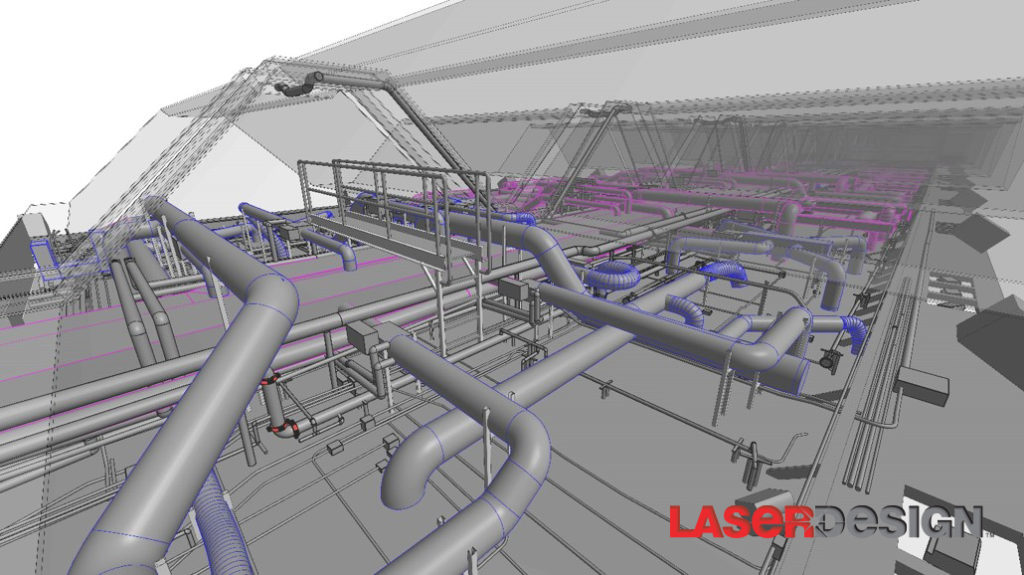

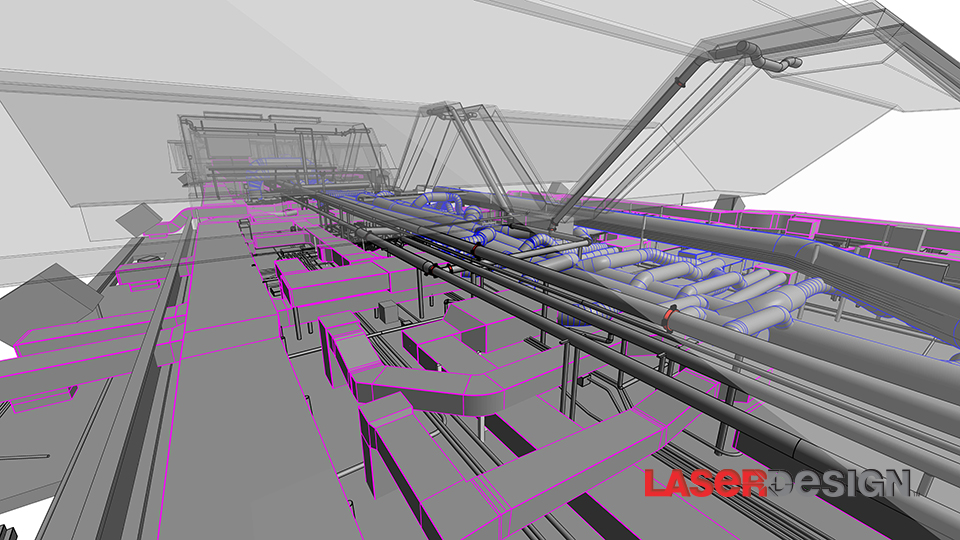

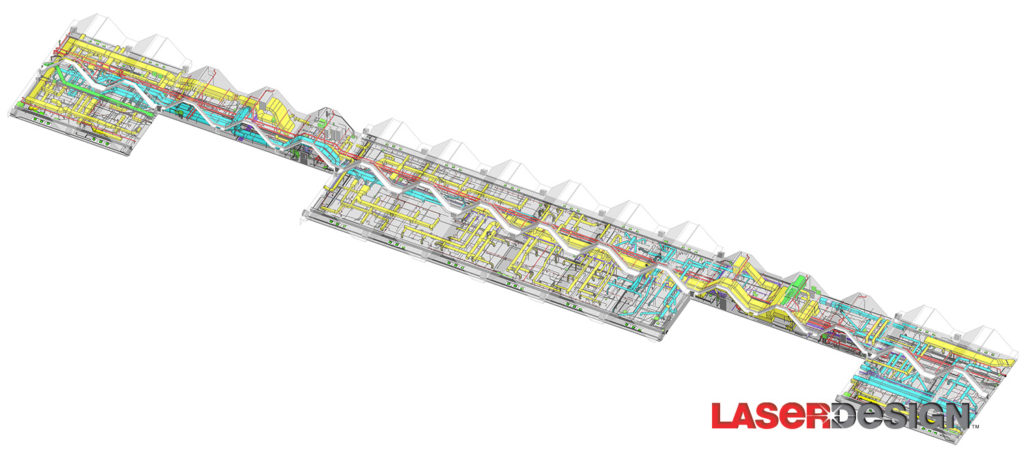

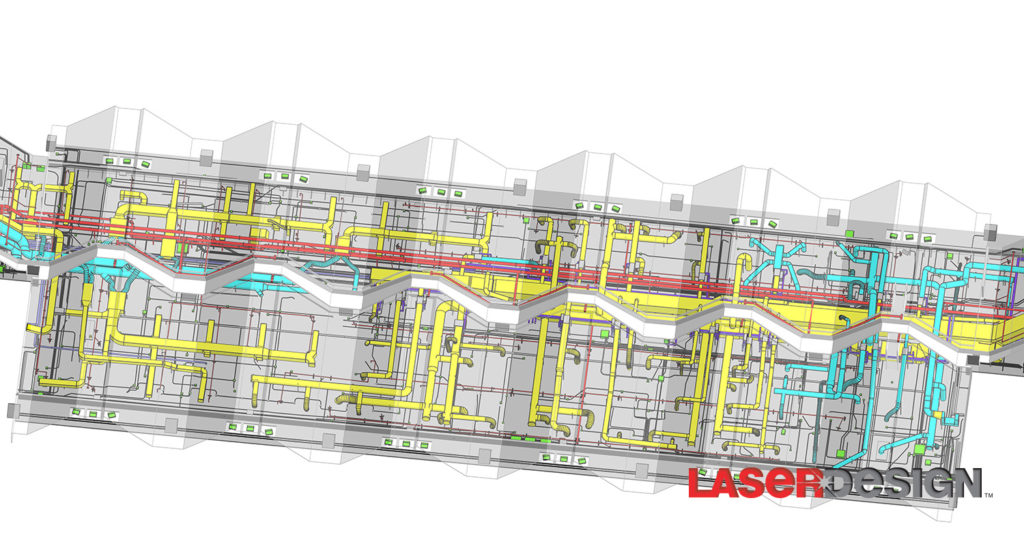

The Laser Design team utilized a number of different scanners (Leica P30 and FARO Focus 120), to laser scan all MEP equipment to capture 3D data (Point Cloud) of existing systems and structural features in mechanical rooms and bays in the terminal. The client also needed all of the ¾ inch conduit to be modeled. Laser Design performed site specific training and security credentials were obtained to provide access to a very secure worksite. Traditional surveying workflow and targeting provided 3D data that is captured in the same coordinate system to register multiple rooms and bays together. Once all the 3d scan data was collected, an as-built 3D CAD (Revit) model was created using the point cloud information to ensure accuracy. Advanced modeling techniques gave Laser Design the edge to produce a highly detailed deliverable that was both efficient and budget friendly.

Results:

The contractor was able to engineer a new design in Revit with confidence and minimal field measurement. Laser scanning helped eliminate wasted time and effort that would usually be spent on traditional hand measurement, as well as reducing rework from inaccurate documentation. Check out the fly through video and other renders.