Laser Design recently worked with a commercial glider operation, Cross Country Soaring, to perform a complete 3D scan of one of their Grob 103 Twin II gliders. Cross Country Soaring is based out of Minneapolis, and the 3D scanning was performed at a hangar at a nearby airport.

How Do You 3D Scan a Glider?

To complete the project, our 3D scanning experts used a combination of the Artec Ray long range 3D scanner and the Artec Leo handheld 3D scanner. The data from the two 3D scanners were combined using Artec Studio software, and the original color data was added to the final model. The resulting 3D model will be used not only for Computational Fluid Dynamics (CFD) testing, but also for promotional and marketing purposes.

The Project, the 3D Scanning Tools, and the Process

The Grob 103 Twin II glider is a two-seater aircraft with a 57-foot wingspan—longer than a city bus. As an unpowered aircraft without the ability to control its own thrust, these gliders leverage weather conditions and thermal columns to adjust altitude, perform aerobatic maneuvers, and ultimately land smoothly and on-target.

Gliders are designed to be as efficient as possible by having a smaller and narrower body but with longer and thinner wings compared to other powered aircraft, all of which reduce drag. Skilled pilots can soar for hundreds of miles when the conditions are right. Woody from “Toy Story” said it best: “That wasn’t flying. That was falling with style.”

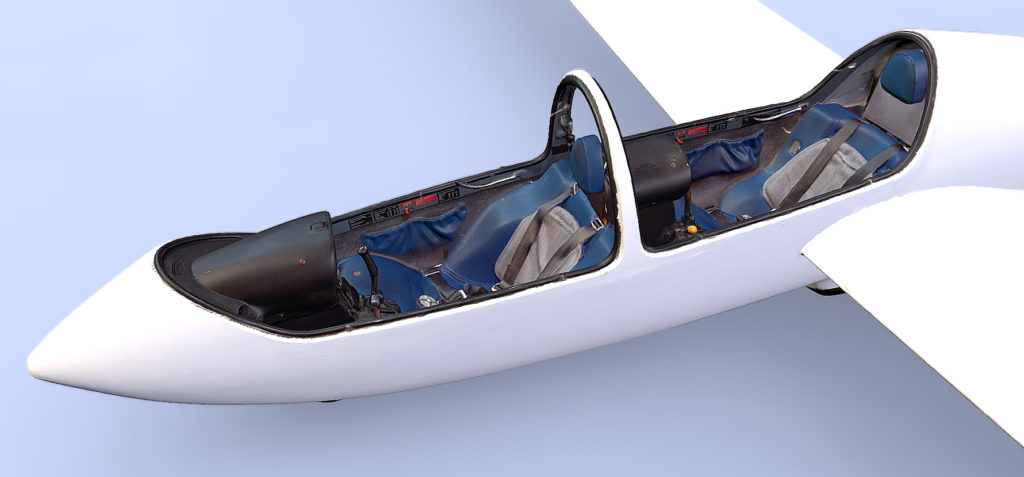

With a sleek and streamlined shape, the glider can be thought of as containing two main zones of consideration for 3D scanning: the interior cockpit, and a combined area containing fuselage, tail, and wings.

3D Scanning the Glider Cockpit

With the help of the Artec Leo 3D, 3D scanning the cockpit was incredibly easy. A Laser Design technician was able to 3D scan the inside from all angles, in full color, and even scan deep within the footwells. The Artec Leo’s integrated display screen provided immediate feedback, showing that we were on the right track.

Parts of the wings and surrounding area were also 3D scanned at the same time to be used for alignment during downstream processing. The Leo provided amazing value in that we could reach the important areas on all sides of the aircraft without needing a single power or USB connection cable! The Artec Leo also enabled us to verify that we captured all of the crucial areas immediately on the job site, without the need to power up a laptop with processing software. This dramatically sped up our 3D scanning time and reduced the time we spent on-site, allowing us to quickly move on to the rest of the glider.

3D Scanning the Body of the Glider

In order to measure the fuselage, tail, and wings of the glider, we utilized the Artec Ray 3D scanner. As one of the newest 3D scanners in Artec’s repertoire, the Ray uses laser technology to collect 3D scan data of up to 110 meters, a distance out of reach for Artec’s other scanning systems.

Most other 3D scanners suffer from an accuracy drop-off over a length of 57 feet, which would result in an inaccurate model that might cause the wings to show up crooked when they should be straight and smooth. A long-range 3D scanner like the Artec Ray was necessary to ensure high accuracy over the very long distance. By mounting the Ray on a tripod, we could raise it fully above the glider to capture the top surfaces, and we could also place it directly on the ground to capture the underside of the wings. This is especially useful for scanning gliders, in particular. Unlike other powered aircraft, the wings of a glider are lower to the ground because they have much smaller landing gears without struts.

Processing With 3D Scanning Software

In just a few hours, the 3D scanning was complete, and the data was taken back to Laser Design’s offices for processing. Both the Ray and Leo datasets were loaded into Artec Studio Software for registration, alignment, and combination. Because the Leo data contained part of the wings, and likewise the Ray data contained seatback and headrest data from the cockpit, the two datasets were easy to align together to enable merging them into a single polygon model. Once this was done, the resulting 3D model was wrapped with the raw color data, creating a textured polygon model. Further downstream processing will include converting the 3D scan shape into a smooth CAD model to be used for Computational Fluid Dynamics (CFD) analysis.

Applications of 3D Scanning

In contrast to the majority of our other 3D scanning projects, Cross Company Soaring didn’t have one specific goal or question in mind—the company plans to use the data and 3D model for a variety of purposes. That was just fine with us, because the beauty of 3D scanning is that this technology is incredibly versatile. The applications for this data are truly limitless!

In fact, here are just some of the possible uses for the type of data we collected for this project:

| ● Computational Fluid Dynamics (CFD) | ● Augmented Reality (AR) |

| ● Finite Element Analysis (FEA) | ● Projection Mapping |

| ● Propulsion | ● Training and Safety |

| ● Control Engineering | ● Human Factors Engineering |

| ● Aircraft Structure Design | ● Competitive Analysis |

| ● Aeroelasticity | ● As-Built Documentation |

| ● Aeroacoustics | ● Aftermarket Parts |

| ● Flight Testing/Simulation | ● Cargo Volume Planning |

| ● Virtual Reality (AR)—Simulation |

And here are some of the aircraft models that have been scanned by the Laser Design Services Team:

| Airplanes | Helicopters | Airships |

|---|---|---|

| ● C-5 Galaxy | ● Sikorsky S-92 | ● HAV 304/Airlander 10 |

| ● C-130 Hercules (Multiple versions) | ● Sikorsky S-76 | |

| ● E8-JSTARS (Boeing 707) | ● Airbus H125 | |

| ● Gulfstream G-550 | ● Airbus H130 | |

| ● V-22 Osprey Tiltrotor | ● Airbus H135 | |

| ● Lockheed P3 Orion | ● Airbus H145 | |

| ● Cessna 172 | ● McDonnell Douglas MD-500 | |

| ● Cessna 182 | ||

| ● Cessna 208 Caravan | ||

| ● Cessna T206 Super Skylane | ||

| ● Grob G103a Twin II Sailplane |

Create Detailed 3D Scans Easily With Artec Scanners

3D scanning large objects has never been easier with the combination of Ray and Leo. Each 3D scanner complements the other so perfectly that even a large glider can be captured in a single morning scanning session lasting just a few hours. In fact, this particular scanning project was completed in time for lunch! Before Artec came along, a 3D scan of this glider in color could easily take an entire day or more to complete—and you would end up with a scan of far lower quality too. For a closer look at exactly what we made, download the content from the scan and the created 3D CAD model on our website!

At Laser Design, we’ve put our years of 3D scanning experience to work by providing smart solutions for thousands of customers. If you need a long range scanner to capture a massive aircraft or building, we can help—in fact, we can help with just about any 3D scanning project. Reach out today to get started.